Carburized tapered drill rod

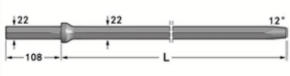

Taper Degree :6°,7°,11°,12° Length:600mm-8000mm Shank:H22x108mm,H25x108mm Material: 23CrNi3Mo

Key words:

Tapered Drill Rod

Product Details

Description

Carburized tapered drill rod is widely used in underground mines and construction projects. Compared with the integral drill steel, there is energy loss in the cone joint of taper rod. The Carburized tapered drill rod can be equipped with a variety of bit to drill holes of different caliber. The bit can be repaired or replaced after wear, greatly reducing the construction cost.

Carburization is a process used to harden the entire Carburized tapered drill rod surface both internally and externally to strengthen and extend the life of the tapered drill rod.

Shank Hexagon: 19*108 mm, 22*108mm, 25*108 mm, 25*159 mm;6°,7°,11°,12°taper degree in most lengths, taper degree of drill steel is mostly imports for excellent drilling productivity.

Performance

Low use cost,low natural power consumption, easy installation and disassembly, long service life.

High strength chromium-molybdenum steel with high fatigue strength and excellent wear resistance

Application

Quarrying

Underground mining

Down the hole rock drilling

Details Form

|

Drill rod |

Length |

Weight (kg) |

HENGLONG P/N |

|

|

|

mm |

foot |

|

|||

|

Hex.taperd rod

|

600 |

2′ |

1.93 |

21H22-7/108-0600-40 |

|

|

800 |

2′6″ |

2.54 |

21H22-7/108-0800-40 |

|

|

|

1000 |

3′3″ |

3.15 |

21H22-7/108-1000-40 |

|

|

|

1200 |

3′9″ |

3.76 |

21H22-7/108-1200-40 |

|

|

|

1500 |

4′11″ |

4.68 |

21H22-7/108-1500-40 |

|

|

|

1600 |

5′3″ |

4.98 |

21H22-7/108-1600-40 |

|

|

|

1800 |

5′9″ |

5.59 |

21H22-7/108-1800-40 |

|

|

|

2000 |

6′7″ |

6.20 |

21H22-7/108-2000-40 |

|

|

|

2200 |

7′2″ |

6.81 |

21H22-7/108-2200-40 |

|

|

|

2300 |

7′6″ |

7.12 |

21H22-7/108-2300-40 |

|

|

|

2400 |

7′9″ |

7.42 |

21H22-7/108-2400-40 |

|

|

|

2500 |

8′2″ |

7.73 |

21H22-7/108-2500-40 |

|

|

|

2600 |

8′8″ |

8.03 |

21H22-7/108-2600-40 |

|

|

|

3000 |

9′10″ |

9.25 |

21H22-7/108-3000-40 |

|

|

|

3500 |

11′5″ |

10.78 |

21H22-7/108-3500-40 |

|

|

|

4000 |

13′1″ |

12.30 |

21H22-7/108-4000-40 |

|

|

|

4500 |

14′8″ |

13.83 |

21H22-7/108-4500-40 |

|

|

|

5000 |

16′4″ |

15.35 |

21H22-7/108-5000-40 |

|

|

|

5500 |

18′1″ |

16.88 |

21H22-7/108-5500-40 |

|

|

|

6000 |

19′7″ |

18.30 |

21H22-7/108-6000-40 |

|

|

|

|

4000 |

13′1″ |

16.1 |

21H25-7/159-4000-40 |

|

|

4700 |

15′4″ |

18.90 |

21H25-7/159-4700-40 |

|

|

|

5000 |

16′4″ |

22.1 |

21H25-7/159-5000-40 |

|

|

|

5500 |

18′1″ |

22.1 |

21H25-7/159-5500-40 |

|

|

|

6000 |

19′7″ |

24.1 |

21H25-7/159-6000-40 |

|

|

|

Hex.22mm Tapered rod,carburizd

|

610 |

2′ |

2.2 |

21H22-11/108-0610-40 |

|

|

1220 |

4′ |

4.1 |

21H22-11/108-1220-40 |

||

|

1830 |

6′ |

5.9 |

21H22-11/108-1830-40 |

||

|

2435 |

8′ |

7.8 |

21H22-11/108-2435-40 |

||

|

3200 |

10′6″ |

10.1 |

21H22-11/108-3200-40 |

||

|

3655 |

12′ |

11.5 |

21H22-11/108-3655-40 |

||

|

4000 |

13′1″ |

12.6 |

21H22-11/108-4000-40 |

||

|

4800 |

15′9″ |

14.9 |

21H22-11/108-4800-40 |

||

|

5600 |

18′4″ |

17.4 |

21H22-11/108-5600-40 |

||

|

6400 |

21′ |

19.8 |

21H22-11/108-6400-40 |

||

|

7200 |

23′6″ |

22.2 |

21H22-11/108-7200-40 |

||

|

8000 |

26′2″ |

24.6 |

21H22-11/108-8000-40 |

||

|

Hex.22mm Tapered rod,carburizd

|

610 |

2′ |

2.20 |

21H22-12/108-0610-40 |

|

|

1220 |

4′ |

4.10 |

21H22-12/108-1220-40 |

||

|

1830 |

6′ |

5.90 |

21H22-12/108-1830-40 |

||

|

2000 |

6′7″ |

6.40 |

21H22-12/108-2000-40 |

||

|

2435 |

8′ |

7.80 |

21H22-12/108-2435-40 |

||

|

2600 |

8′8″ |

8.30 |

21H22-12/108-2600-40 |

||

|

3200 |

10′6″ |

10.10 |

21H22-12/108-3200-40 |

||

|

3655 |

12′ |

11.50 |

21H22-12/108-3655-40 |

||

|

4000 |

13′1″ |

12.60 |

21H22-12/108-4000-40 |

||

|

4800 |

15′9″ |

14.90 |

21H22-12/108-4800-40 |

||

|

5600 |

18′4″ |

17.40 |

21H22-12/108-5600-40 |

||

|

6400 |

21′ |

19.80 |

21H22-12/108-6400-40 |

||

|

7200 |

23′6″ |

22.20 |

21H22-12/108-7200-40 |

||

|

8000 |

26′2″ |

24.60 |

21H22-12/108-8000-40 |

||

|

Hex.25mm Tapered rod,carburizd

|

1830 |

6′ |

7.96 |

21H25-12/159-1830-40 |

|

|

2435 |

8′ |

10.38 |

21H25-12/159-2435-40 |

||

|

3050 |

10′ |

12.84 |

21H25-12/159-3050-40 |

||

|

3655 |

12′ |

15.26 |

21H25-12/159-3655-40 |

||

|

3965 |

13′ |

16.50 |

21H25-12/159-3965-40 |

||

|

4270 |

14′ |

17.72 |

21H25-12/159-4270-40 |

||

|

4880 |

16′ |

20.16 |

21H25-12/159-4880-40 |

||

|

5530 |

18′ |

22.76 |

21H25-12/159-5530-40 |

||

|

6095 |

20′ |

25.02 |

21H25-12/159-6095-40 |

||

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

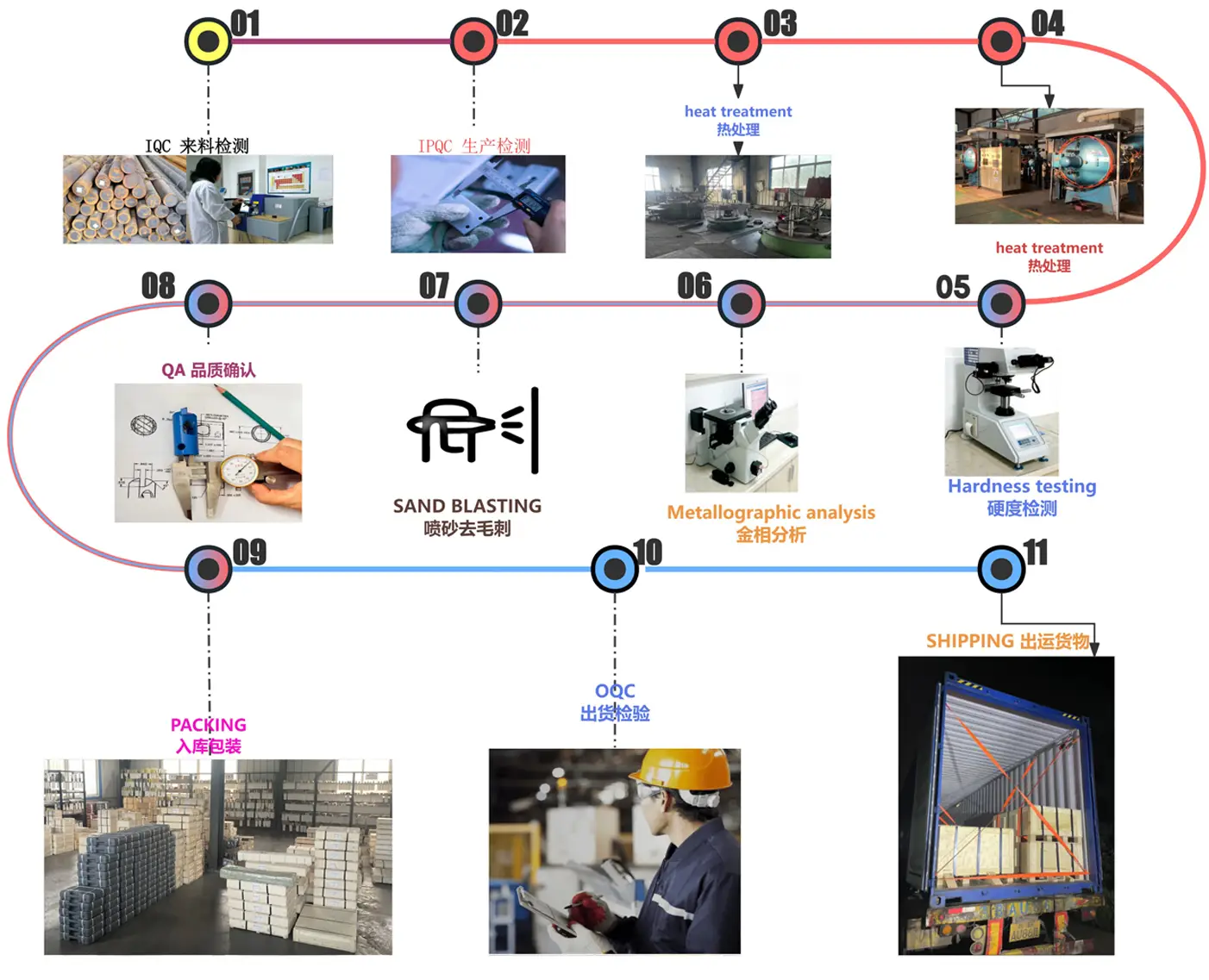

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE