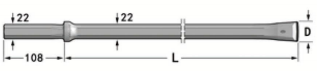

Chisel Bit Integral Rod

Head Diameter:26mm~45mm

Effective length:600~6000mm

Material: Z708(40SiMnCrNiMo)/55SiMnMo

Key words:

Integral Drill Rod

Product Details

Description

HENGLONG chisel bit integral rods have the integral design of drill bits, drill rods and shank adapters. As it is long enough and is able to effectively reduce energy loss, the integral drill rod is suitable for underground mining and drilling small hole that is 24 to 44mm in diameter. The integral drill rod is usually used in air-leg and hand-held rock drills. When the rock is soft, using HENGLONG integral drill rods can speed up the drilling process. The integral drill rods have the advantages of reducing energy loss, improving drilling effect and efficiency.

chisel bit integral rod is used by a hand held drill machine in Under-ground mining and for small hole drilling, equipped with small power rock drills, like air leg rock drills,hand held rock drills, etc. It can reduces the expense of impact energy, improves the drilling speed and efficiency, also it can be used for drilling bore hole diameter from

30mm to 41mm usually. Regarding Integral drill steels,the quality of a steel material and a tungsten carbide is very important to get good drilling performance.

H22 one-piece bit steel, with H22 x 108 mm shank, is the most common type in the large stone quarrying industry. The product range includes drill bits Ø26-40 mm in diameter and 0.6-6 m in length.

Performance

chisel bit integral rod have the advantages of reducing energy loss, improving drilling effect and efficiency.

Application

chisel bit integral rod is used by a hand held drill machine in Under-ground mining and for small hole drilling.

Widely used in Dimensional Stone Quarrying Industry

Details Form

|

19mm |

Length |

Bit Dia. |

Weight approx kg |

HENGLONG P/N |

|

|

mm |

foot |

||||

|

Chisel bit integral 19mmX108mm Shank 19mmX108mm

|

400 |

1'4" |

29 |

1.3 |

5H19-291508-0400-40-2 |

|

500 |

1'8" |

29 |

1.5 |

5H19-291508-0500-40-2 |

|

|

800 |

2'7" |

28 |

2.2 |

5H19-281508-0800-40-2 |

|

|

1000 |

3'33/8" |

28 |

2.6 |

5H19-281508-1000-40-2 |

|

|

1200 |

3'11" |

27 |

3.0 |

5H19-271508-1200-40-2 |

|

|

1600 |

5'3" |

27 |

3.9 |

5H19-271508-1600-40-2 |

|

|

2400 |

7'10" |

26 |

5.7 |

5H19-261508-2400-40-2 |

|

|

3200 |

10'6" |

25 |

7.5 |

5H19-251508-3200-40-2 |

|

|

4000 |

13'1" |

24 |

9.2 |

5H19-241508-4000-40-2 |

|

|

|

|

|

|

|

|

|

400 |

1'4" |

24 |

1.3 |

5H19-241508-0400-40-2 |

|

|

800 |

2'7" |

23 |

2.2 |

5H19-231508-0800-40-2 |

|

|

|

|

|

|

|

|

|

600 |

2' |

27 |

1.7 |

5H19-271508-0600-40-2 |

|

|

1200 |

3'11" |

26 |

3.0 |

5H19-261508-1200-40-2 |

|

|

2000 |

6'7" |

24 |

4.8 |

5H19-241508-2000-40-2 |

|

|

2400 |

7'10" |

24 |

5.7 |

5H19-241508-2400-40-2 |

|

|

2700 |

8'10" |

24 |

6.3 |

5H19-241508-2700-40-2 |

|

|

|

|

|

|

|

|

|

400 |

1'4" |

35 |

1.3 |

5H19-351508-0400-40-2 |

|

|

800 |

2'7" |

34 |

2.2 |

5H19-341508-0800-40-2 |

|

|

Chisel bit integral 22mmX108mm Shank 22mmX108mm

|

400 |

1'4" |

29 |

1.5 |

5H19-291508-0400-40-2 |

|

400 |

1'4" |

29 |

1.5 |

5H19-291508-0400-40-2 |

|

|

600 |

2' |

27 |

1.7 |

5H19-291508-0600-40-2 |

|

|

800 |

2'7" |

28 |

2.2 |

5H19-291508-0800-40-2 |

|

|

800 |

2'7" |

28 |

2.2 |

5H19-291508-0800-40-2 |

|

|

1200 |

3'11" |

27 |

3.0 |

5H19-291508-1200-40-2 |

|

|

1600 |

5'3" |

27 |

3.9 |

5H19-291508-1600-40-2 |

|

|

2000 |

6'7" |

24 |

4.8 |

5H19-291508-2000-40-2 |

|

|

2400 |

7'10" |

26 |

5.7 |

5H19-291508-2400-40-2 |

|

|

3200 |

10'6" |

25 |

7.5 |

5H19-291508-3200-40-2 |

|

|

19mm |

Length (mm) |

Bit Dia. |

Turned length |

Weight approx kg |

HENGLONG P/N |

|

Plug hole integral steels 19mmX108mm Shank 19mmX108mm

|

210 |

17 |

150 |

0.7 |

5H19-171308-0210-40-2 |

|

210 |

20 |

150 |

0.7 |

5H19-201308-0210-40-2 |

|

|

210 |

22 |

150 |

0.7 |

5H19-221308-0210-40-2 |

|

|

260 |

20 |

200 |

0.8 |

5H19-201308-0260-40-2 |

|

|

260 |

22 |

200 |

0.8 |

5H19-221308-0260-40-2 |

|

|

310 |

22 |

250 |

0.9 |

5H19-221308-0310-40-2 |

|

|

340 |

20 |

280 |

1.0 |

5H19-201308-0340-40-2 |

|

|

19mmX82mm Shank 19mmX82mm

|

210 |

20 |

150 |

0.7 |

5H19-201308-0210-40-2 |

|

210 |

22 |

150 |

0.7 |

5H19-221308-0210-40-2 |

|

|

22mm |

Length |

Bit Dia. |

Weight approx kg |

HENGLONG P/N |

|

|

mm |

foot |

||||

|

Chisel bit integral 22mmX108mm Shank 22mmX108mm

|

800 |

2'7" |

34 |

3.0 |

5H22-341810-0800-40-2 |

|

1600 |

5'3" |

33 |

5.2 |

5H22-331810-1600-40-2 |

|

|

2400 |

7'10" |

32 |

8.0 |

5H22-321808-2400-40-2 |

|

|

3200 |

10'6" |

31 |

10.2 |

5H22-311808-3200-40-2 |

|

|

4000 |

13'1" |

30 |

12.9 |

5H22-301808-4000-40-2 |

|

|

4800 |

15'9" |

29 |

15.1 |

5H22-291508-4800-40-2 |

|

|

5600 |

18'4" |

28 |

17.6 |

5H22-281508-5600-40-2 |

|

|

6400 |

21' |

27 |

20.1 |

5H22-271508-6400-40-2 |

|

|

7200 |

23'6" |

26 |

22.5 |

5H22-261508-7200-40-2 |

|

|

800 |

2'7" |

34 |

3.0 |

5H22-341810-0800-40-2 |

|

|

1600 |

5'3" |

33 |

5.2 |

5H22-331810-1600-40-2 |

|

|

2400 |

7'10" |

32 |

8.0 |

5H22-321808-2400-40-2 |

|

|

3200 |

10'6" |

31 |

10.2 |

5H22-311808-3200-40-2 |

|

|

4000 |

13'1" |

30 |

12.9 |

5H22-301808-4000-40-2 |

|

|

4800 |

15'9" |

29 |

15.1 |

5H22-291508-4800-40-2 |

|

|

5600 |

18'4" |

28 |

17.6 |

5H22-281508-5600-40-2 |

|

|

6400 |

21' |

27 |

20.1 |

5H22-271508-6400-40-2 |

|

|

7200 |

23'6" |

26 |

22.5 |

5H22-261508-7200-40-2 |

|

|

8000 |

26'2" |

31 |

25.0 |

5H19-311508-8000-40-2 |

|

|

400 |

1'4" |

34 |

1.7 |

5H22-341810-0400-40-2 |

|

|

800 |

2'7" |

33 |

3.0 |

5H22-331810-0800-40-2 |

|

|

1200 |

3'11" |

32 |

4.1 |

5H22-321808-1200-40-2 |

|

|

1600 |

5'3" |

31 |

5.2 |

5H22-311808-1600-40-2 |

|

|

2000 |

6'7" |

30 |

6.7 |

5H22-301808-2000-40-2 |

|

|

600 |

2' |

41 |

2.4 |

5H22-411810-0600-40-2 |

|

|

1200 |

3'11" |

40 |

4.3 |

5H22-401810-1200-40-2 |

|

|

1800 |

5'11" |

39 |

6.2 |

5H22-391810-1800-40-2 |

|

|

2400 |

7'10" |

38 |

8.0 |

5H22-381810-2400-40-2 |

|

|

400 |

1'4" |

41 |

1.7 |

5H22-411810-0400-40-2 |

|

|

800 |

2'7" |

29 |

3.0 |

5H22-291508-0800-40-2 |

|

|

800 |

2'7" |

38 |

3.1 |

5H22-381810-0800-40-2 |

|

|

1200 |

3'11" |

39 |

4.3 |

5H22-391810-1200-40-2 |

|

|

1600 |

5'3" |

36 |

5.2 |

5H22-361810-1600-40-2 |

|

|

1800 |

5'11" |

36 |

6.0 |

5H22-361810-1800-40-2 |

|

|

2000 |

6'7" |

32 |

6.7 |

5H22-321808-2000-40-2 |

|

|

2400 |

7'10" |

27 |

8.0 |

5H22-271508-2400-40-2 |

|

|

3200 |

10'6" |

27 |

10.2 |

5H22-271508-3200-40-2 |

|

|

3200 |

10'6" |

32 |

10.3 |

5H22-321808-3200-40-2 |

|

|

6400 |

21' |

30 |

20.1 |

5H22-301808-6400-40-2 |

|

|

8000 |

26'2" |

26 |

25.0 |

5H22-261508-8000-40-2 |

|

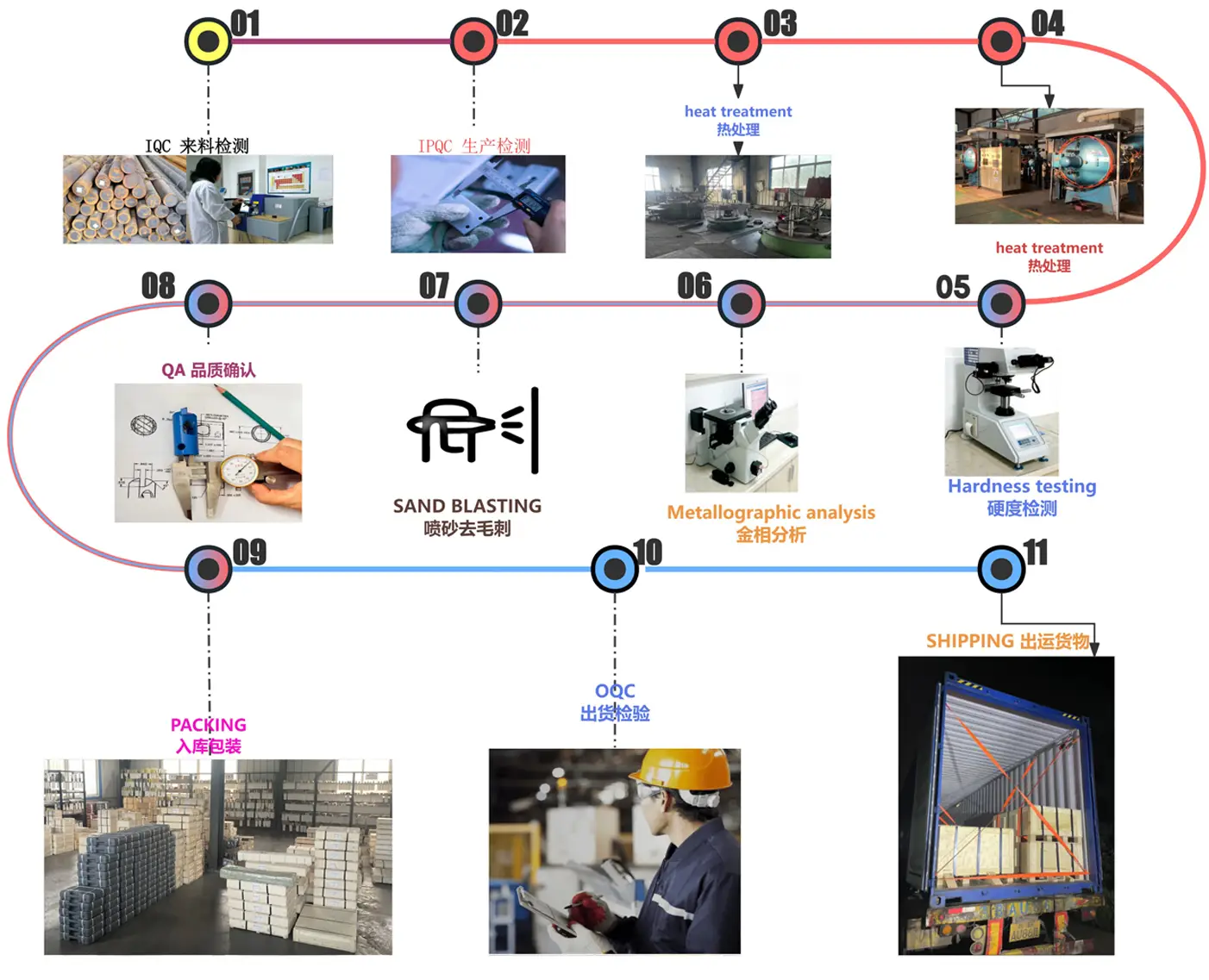

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE