Coal mining PDC drill bit

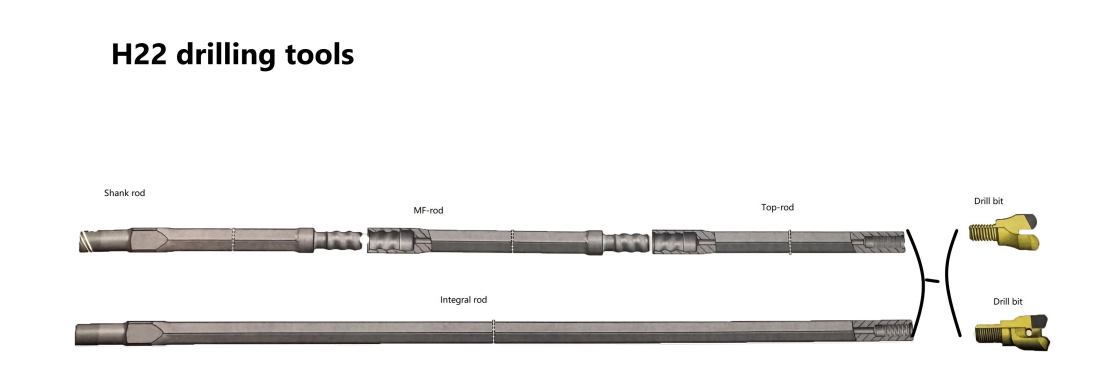

Type:H19/H22drilling tools

Diameter:5-28mm,32,42mm,etc

Thread Size:M14*1.5, M12*2,M16*1.5 ,M16*2

Working Length:6.5

Processing Type:Forging

Customized:Customized

Steel grade:40Cr,42CrMo, 4140

Carbide:Diamond /YG9C YG8C

Application:Coal Mine,Dam and Roadway Construction

Key words:

Coal Mining Tools

Product Details

Description

Polycrystalline Diamond Compact(PDC), is manufactured with a diamond layer attached to a carbide substrate. Combining the properties of both super hardness and abrasion resistance of diamond with outstanding strength and toughness of of tungsten carbide, PDC has been widely used in mechanical industry,oil well drilling,geological prospecting drilling and coal mining. It possess of high wear resistance like diamond, at the same time the impact resistance like hard alloy and that’s made it the best material as a drill bit cutter. Reinforced PDC has higher dense diamond powder, claw hard alloy substrate made the two layers solid as whole one. So, the re -inforced PDC of supper wear resistance, longer service life and high efficiency.

PDC anchor shank bit is the most basic part of roadway support in coal mines. It can bound the surrounding rock of roadway together, and make the surrounding rock to support itself. Roofbolt drill bit is a kind of drilling tool for fixing anchor bolt of coal mine. The two wings of our PDC roofbolt drill bit adopt PDC (Polycrystalline Diamond Compact) as the cutting tooth, the application of PDC has greatly improved the drilling efficiency of roofbolt drill bit, and is taking the place of tungsten carbide roofbolt drill bit gradually.

Performance

1. The cutting tools adopts new type superhard material;shelf life of drill bit is high.

2. Drilling efficiency of medium hard and harder stratum can be greatly improved.

3. Cutting edge is wearable, no need of polishing, easy to operate.

Application

Anchor-shank drill bit with PDC cutter is mainly applied to the anchor network support hole drilling in underground coal mine, transportation,water conservancy and hydrpower,etc.

Specification

|

Type |

D(mm) |

H(mm) |

Wing Qua PCD bit for |

PDC cutter |

Waterpore |

||

|

|

|

|

|

Shape |

Quantity |

Quantity |

D(mm) |

|

ZW28A |

28 |

48 |

2 |

half |

2 |

1 |

5 |

|

ZW28B |

28 |

48 |

2 |

whole |

2 |

1 |

5 |

|

ZW30A |

30 |

48 |

2 |

half |

2 |

1 |

5 |

|

ZW30B |

30 |

48 |

2 |

whole |

2 |

1 |

5 |

|

ZW32A |

32 |

48 |

2 |

half |

2 |

1 |

5 |

|

ZW32B |

32 |

48 |

2 |

whole |

2 |

1 |

5 |

|

ZW42B |

42 |

60 |

3 |

Half+whole |

2+2 |

3 |

5 |

Related products:

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

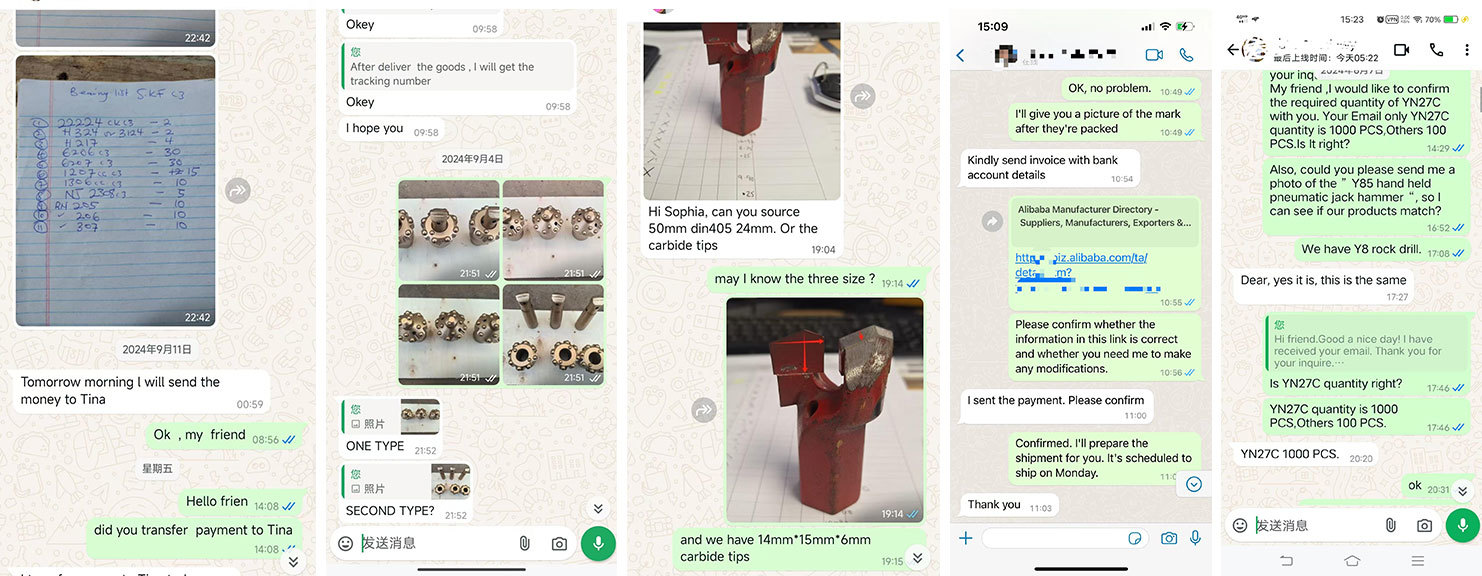

Customer visit

Production

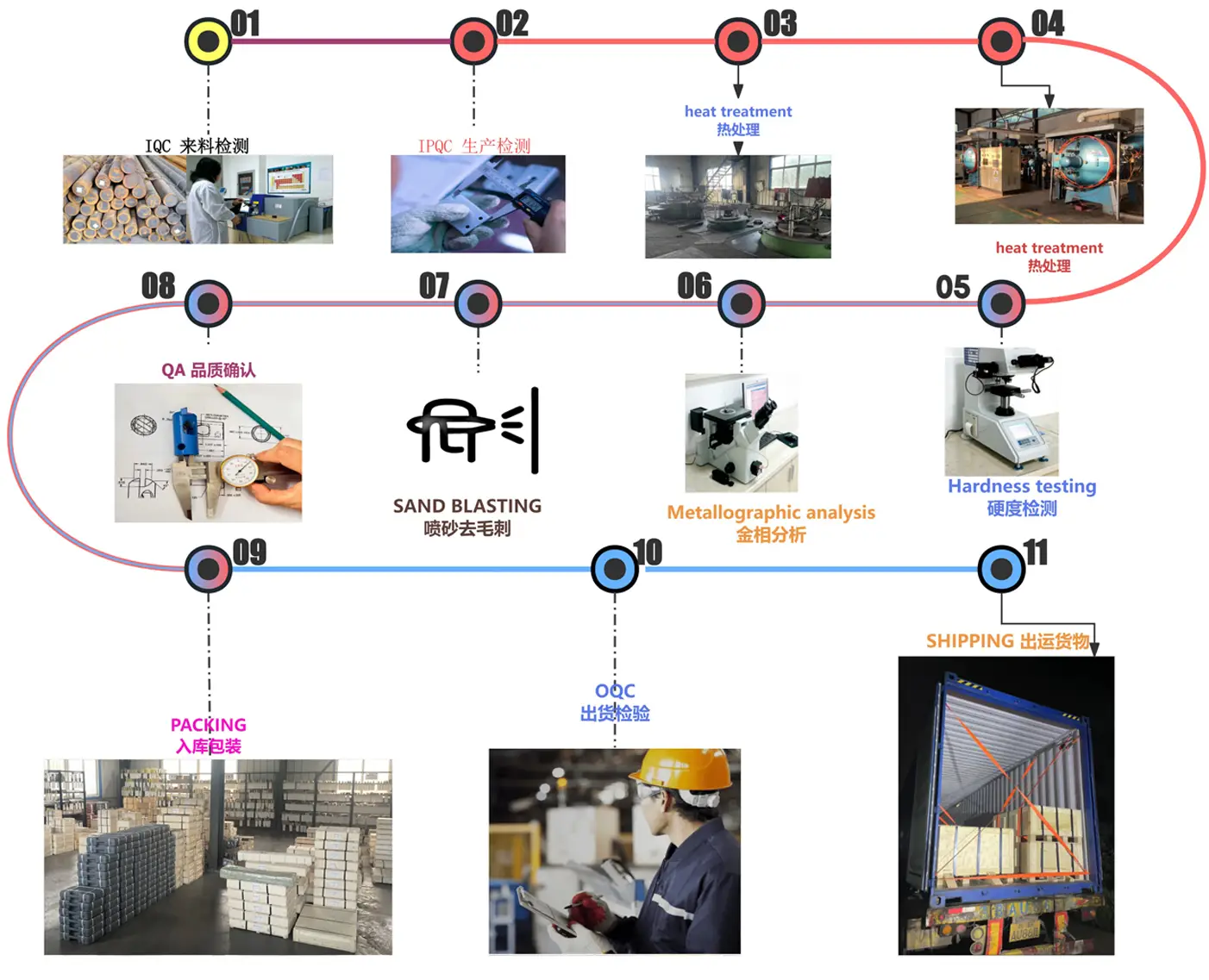

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE