Conical pick tools

length:160mm;

Weight:1036g;

Material:35CrNiMoVa/XQ26;

Color:Glass Gray;

Key words:

Coal Mining Tools

Product Details

Description

Conical Pick tools are an important part of coal mining, roadway excavation, and rock crushing during construction. Picks are also one of the main consumables.

Conical pick tools are robust cutting tools used in rock drilling machinery to remove or break through hard surfaces such as rocks, concrete, and asphalt. These tools are designed with a conical shape, ensuring efficient penetration and material removal. With their sturdy construction and wear-resistant characteristics, conical pick tools are essential components in various types of drilling equipment.

Conical pick tools are indispensable components in rock drilling machinery, revolutionizing the mining, construction, and excavation industries.

No matter the application, turn to HENGLONG DRILL for expert tooling & wear solutions to get your job done efficiently and economically.

Performance

The selection of appropriate conical pick tools can improve drilling efficiency, reduce operational costs, and boost overall productivity.No matter the application, turn to Kennametal for expert tooling & wear solutions to get your job done efficiently and economically.

Application

Conical pick tools find extensive applications in the field of rock drilling machinery, especially in industries such as mining, construction, and tunneling. These tools are primarily utilized in:

- Coal mining: Conical pick tools are used to extract coal from underground mines efficiently.

- Road construction: They are employed to break through asphalt surfaces during road construction or repair.

- Underground excavation: Conical pick tools are indispensable in tunneling projects, aiding in the excavation of tunnels for transportation or infrastructure development.

The selection of appropriate conical pick tools can improve drilling efficiency, reduce operational costs, and boost overall productivity.

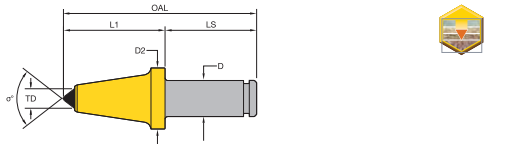

Specification

|

■30mm(1.18")conical pick tolls●standard

|

||||||||||||||||||

| D | TD | L1 | D2 | LS | OAL | |||||||||||||

| order | iteam | mm | in | mm | in | σ° | mm | in | mm | in | mm | in | mm | in | ||||

| 2220813 1950491 |

K1 NB K1 K |

30 30 |

1.18 1.18 |

18 18 |

.69 .69 |

93.0 93.0 |

64 69 |

2.50 2.71 |

48 48 |

1.89 1.89 |

75 80 |

2.95 3.17 |

139 149 |

5.45 5.88 |

||||

| 2034016 | K1K NB | 30 | 1.18 | 18 | .69 | 93.0 | 69 | 2.71 | 48 | 1.89 | 80 | 3.17 | 149 | 5.88 | ||||

| 2506006 | U85K 3.1.48 | 30 | 1.18 | 12 | .48 | 75.0 | 79 | 3.09 | 51 | 2.00 | 72 | 2.84 | 151 | 5.93 | ||||

| 1924847 | U119K8016BN | 30 | 1.18 | 16 | .63 | _ | 79 | 3.13 | 50 | 1.97 | 77 | 3.03 | 156 | 6.16 | ||||

| 3029709 | U82HDLR-12.5NB | 30 | 1.18 | 12 | .48 | 75 | 80 | 3.13 | 51 | 2.00 | 72 | 2.84 | 152 | 5.97 | ||||

| 1107477 | U1198016 | 30 | 1.18 | 16 | .63 | 75.0 | 80 | 3.15 | 56 | 2.20 | 76 | 3.00 | 156 | 6.15 | ||||

| 1010562 | U119K 8016 | 30 | 1.18 | 16 | .63 | 75.0 | 80 | 3.16 | 50 | 1.97 | 77 | 3.03 | 157 | 6.19 | ||||

| 3029710 | UB4HDLR CH 16NB | 30 | 1.18 | 16 | .64 | 75 | 80 | 3.16 | 51 | 2.00 | 72 | 2.84 | 152 | 6.00 | ||||

| 3550051 | U119KSL 8018.6BN | 29 | 1.18 | 19 | .73 | _ | 81 | 3.18 | 50 | 1.96 | 76 | 3.00 | 157 | 6.18 | ||||

| 2527413 | U85K 3.216NB | 30 | 1.18 | 16 | .64 | 75.0 | 83 | 3.25 | 51 | 2.00 | 72 | 2.84 | 155 | 6.09 | ||||

| 1075595 | U85AUS 16NB | 30 | 1.18 | 16 | .64 | 75.0 | 85 | 3.33 | 56 | 2.20 | 76 | 3.00 | 161 | 6.33 | ||||

| 2234432 | U85HDHF | 30 | 1.18 | 12 | .48 | 75.0 | 86 | 3.37 | 56 | 2.20 | 76 | 3.00 | 162 | 6.37 | ||||

| 1010407 | U85HD | 30 | 1.18 | 12 | .48 | 75.0 | 86 | 3.37 | 56 | 2.20 | 76 | 3.00 | 162 | 6.37 | ||||

| 4058676 | U85HD X | 30 | 1.18 | 12 | .48 | 75.0 | 86 | 3.37 | 56 | 2.20 | 76 | 3.00 | 162 | 6.37 | ||||

| 1992213 | K1461K | 30 | 1.18 | 12 | .49 | 75.0 | 88 | 3.46 | 48 | 1.89 | 81 | 3.18 | 169 | 6.64 | ||||

| 2222931 | K11K NB | 30 | 1.18 | 18 | .69 | 93.0 | 89 | 3.50 | 48 | 1.89 | 81 | 3.17 | 169 | 6.67 | ||||

| 2222840 | K1-1-65-H | 30 | 1.18 | 18 | .69 | 93.0 | 89 | 3.49 | 65 | 2.56 | 75 | 2.95 | 164 | 6.44 | ||||

| 2222842 | K1-1-SM-65-H | 30 | 1.18 | 20 | .77 | 90.0 | 89 | 3.50 | 65 | 2.56 | 75 | 2.96 | 164 | 6.46 | ||||

| 3004869 | U85ABM 9116NB | 30 | 1.18 | 16 | .64 | 75.0 | 91 | 3.59 | 51 | 2.00 | 82 | 3.23 | 173 | 6.82 | ||||

| 1010409 | UC85KSA | 30 | 1.18 | 16 | 0.63 | 75.0 | 91 | 3.59 | 56 | 2.20 | 72 | 2.84 | 163 | 6.43 | ||||

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

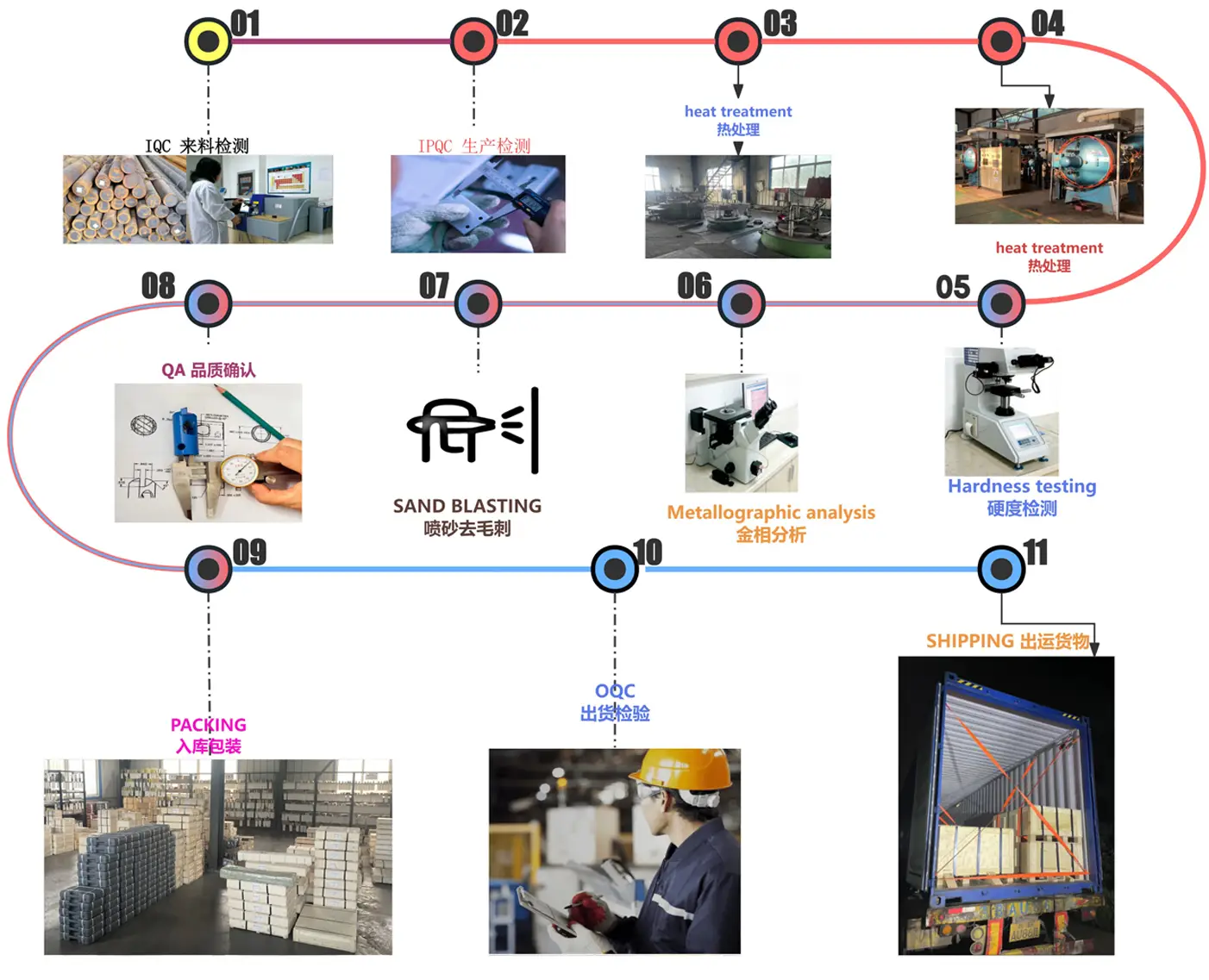

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE