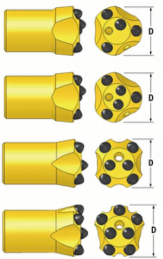

Connical button bit

Button type: conical Button

Painting:ZINC( inner hole)

Carbide Brand and Grade :ZCC/YK05

Steel grade :45CrNiMoVA

Key words:

Tapered Button Bit

Product Details

Description

Tungsten Carbide conical Button Drill Bits are the main type of rock drilling tools. .Material of tungsten carbide taper button drill bits:High quality carbide and high quality steel;Grades of high quality tungsten carbide chisel drill bits as following :YK05(T6)、KD10H、YG9C、YK15.6、YK20;

Performance

1.Tungsten carbide taper button drill bits connect with tapered drill rod perfectly for drilling holes

2.Stable and mature welding technology ensure high quality of bits

3.Accurate dimension of taper degree perfectly matches the rods

4.work reliable and very cost-effective

5.High grade tungsten carbide inserts

6 Bit bodies manufactured from high grade steel and processed using state-of-the-art CNC machinery and heat treatment

Application

Tapered drill bits are used in granite and marble quarry, gold mine, railway, tunnel, etc. for drilling

Details Form

| Drill bit | Diameter | Alloy quantity | Number of water holes | Weight (kg) | HENGLONG P/N | ||||

| mm | inch | Core teeth | Side teeth | inclination | just | side | |||

|

Button bit ,Short skirt

|

32 | 1 1/4 | 1×8 | 3×8 | 35° | 1 | 2 | 0.24 | 1431-321122-18/38-45-51 |

| 32 | 1 1/4 | 2×7 | 5×7 | 40° | 1 | 1 | 0.24 | 1431-321122-27/57-45-51 | |

| 33 | 1 19/64 | 2×7 | 4×7 | 40° | 1 | 1 | 0.25 | 1431-331122-27/47-45-51 | |

| 34 | 1 11/32 | 2×7 | 4×7 | 40° | 1 | 1 | 0.29 | 1431-341122-27/47-45-51 | |

| 35 | 1 3/8 | 2×7 | 5×7 | 35° | 1 | 1 | 0.33 | 1431-351122-27/57-45-51 | |

| 35 | 1 3/8 | 2×7 | 5×8 | 35° | 1 | 1 | 0.33 | 1431-351122-27/58-45-51 | |

| 36 | 1 27/64 | 1×8 | 3×9 | 40° | 1 | 1 | 0.36 | 1431-361122-18/39-45-51 | |

| 36 | 1 27/64 | 2×7 | 4×7 | 40° | 1 | 1 | 0.36 | 1431-361122-27/47-45-51 | |

| 36 | 1 27/64 | 2×7 | 5×8 | 35° | 1 | 1 | 0.36 | 1431-361122-27/58-45-51 | |

| 38 | 1 1/2 | 1×9 | 3×9 | 40° | 1 | 1 | 0.39 | 1431-381122-19/39-45-51 | |

| 38 | 1 1/2 | 2×8 | 3×9 | 40° | 1 | 1 | 0.39 | 1431-381122-28/39-45-51 | |

| 38 | 1 1/2 | 2×7 | 5×8 | 35° | 1 | 1 | 0.39 | 1431-381122-27/58-45-51 | |

| 38 | 1 1/2 | 2×7 | 5×9 | 35° | 1 | 1 | 0.39 | 1431-381122-27/59-45-51 | |

| 40 | 1 37/64 | 1×9 | 3×9 | 40° | 1 | 1 | 0.4 | 1431-401122-19/39-45-51 | |

| 40 | 1 37/64 | 2×8 | 3×9 | 40° | 1 | 1 | 0.4 | 1431-401122-28/39-45-51 | |

| 40 | 1 37/64 | 2×9 | 3×9 | 40° | 1 | 2 | 0.4 | 1431-401122-29/39-45-51 | |

| 40 | 1 37/64 | 2×7 | 5×9 | 35° | 1 | 1 | 0.4 | 1431-401122-27/59-45-51 | |

| 40 | 1 37/64 | 2×8 | 5×9 | 35° | 1 | 1 | 0.4 | 1431-401122-28/59-45-51 | |

| 41 | 1 5/8 | 2×7 | 5×9 | 35° | 1 | 1 | 0.41 | 1431-411122-27/59-45-51 | |

|

Long skirt

|

32 | 1 1/4 | 2×7 | 5×7 | 35° | 1 | 1 | 0.3 | 1435-321122-27/57-45-51 |

| 33 | 1 19/64 | 2×7 | 5×7 | 35° | 1 | 1 | 0.31 | 1435-331122-27/57-45-51 | |

| 33 | 1 19/64 | 2×7 | 6×7 | 40° | 2 | 1 | 0.31 | 1435-331122-27/67-45-51 | |

| 35 | 1 3/8 | 2×7 | 6×7 | 40° | 2 | 1 | 0.35 | 1435-351122-27/67-45-51 | |

| 38 | 1 1/2 | 2×7 | 5×9 | 35° | 1 | 1 | 0.41 | 1435-381122-27/59-45-51 | |

| 41 | 1 5/8 | 2×7 | 5×9 | 35° | 1 | 1 | 0.42 | 1435-411122-27/59-45-51 | |

|

Long skirt

|

35 | 1 3/8 | 2×7 | 5×9 | 35° | 1 | 1 | 0.38 | 1435-351125-27/59-45-51 |

| 36 | 1 27/64 | 2×7 | 5×9 | 35° | 1 | 1 | 0.39 | 1435-361125-27/59-45-51 | |

| 38 | 1 1/2 | 2×7 | 5×9 | 35° | 1 | 1 | 0.41 | 1435-381125-27/59-45-51 | |

| 41 | 1 5/8 | 2×7 | 5×9 | 35° | 1 | 1 | 0.42 | 1435-411125-27/59-45-51 | |

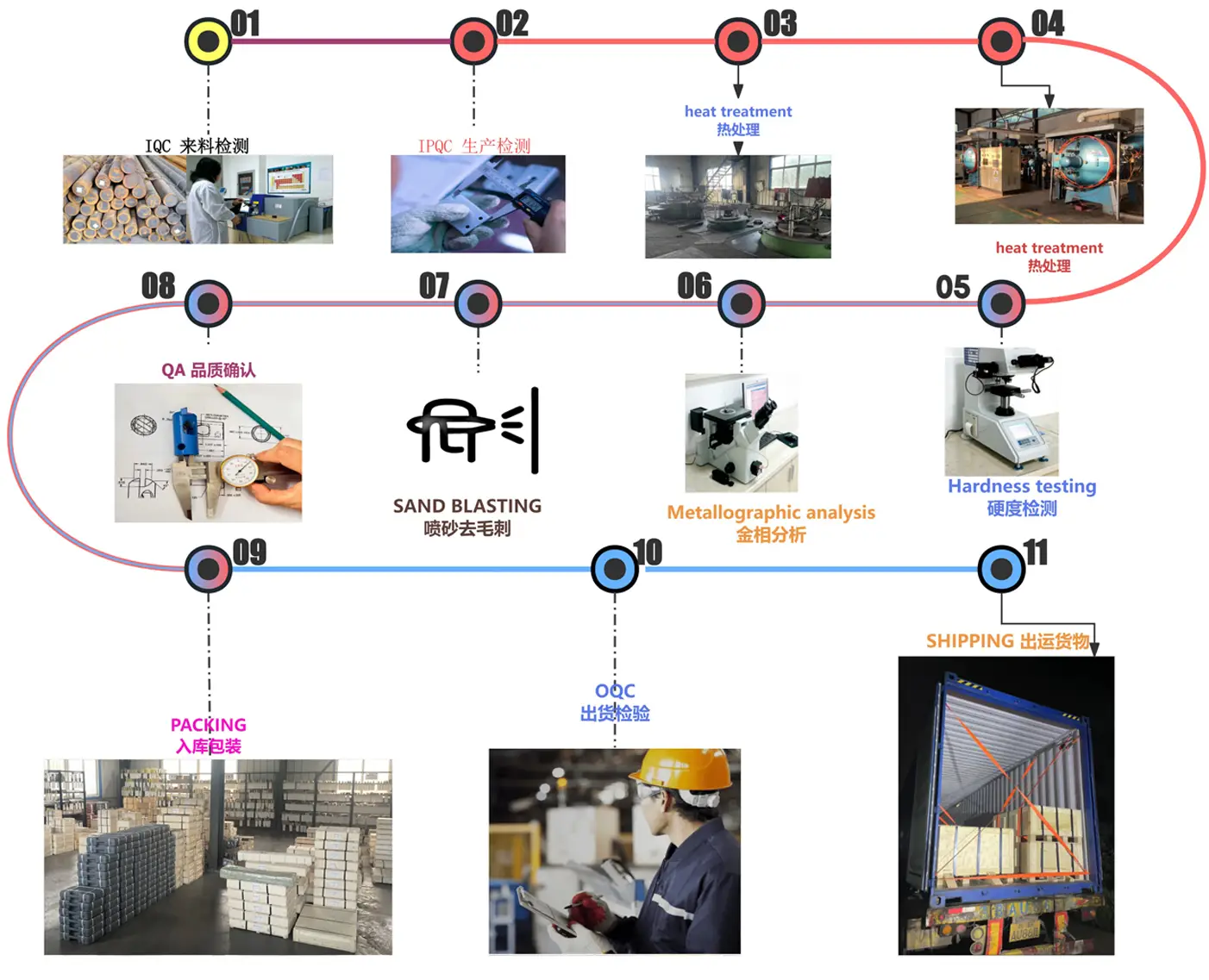

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

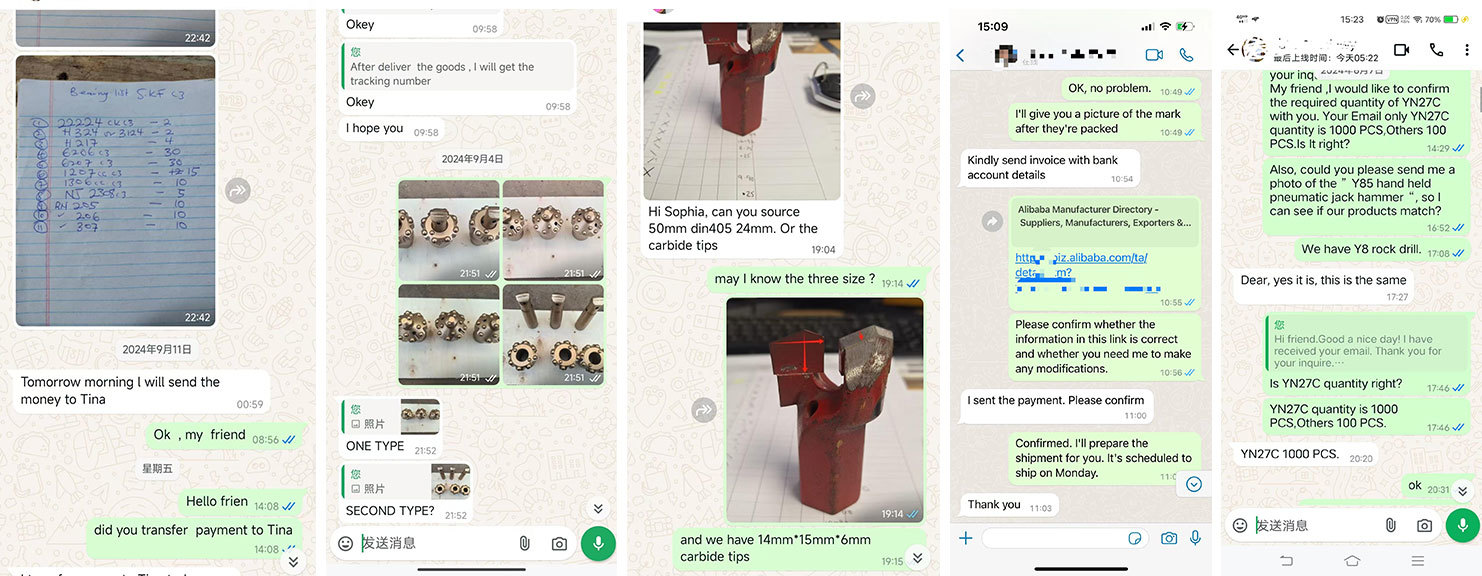

Customer visit

Production

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE