DTH & Top hammer double casing drill bits

Reamed diameter:125mm

Drill bit diameter:83mm

Material:alloy steel

Key words:

DTH hammer tools

Product Details

Description:

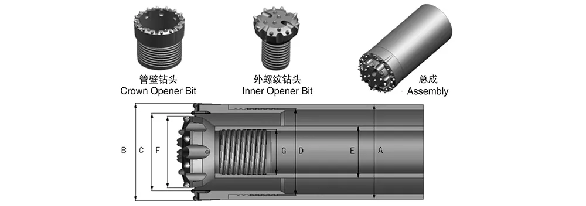

DTH & Top hammer double casing drill bits utilizes a rotary head to drive the outer casing equipped with a tungsten carbide crown and a hydraulic drifter (top hammer) to drive the inner drill string equipped with a percussive drill bit. This is an excellent method for drilling straight holes in varying ground conditions. The water and compressed air can be both provided as power.

Double casing drilling system Top hammer type drilling inside the casing DTH hammer type drilling inside the casing Features Hardening treatment of the part’s surface: with longer operating life and excellent anti-wear properties. Simple Structure: greatly minimize the chances of structural.

The two rotary heads are typically mounted on separate sleds which can be adjusted independently to control the position of the inner string in relation to the casing bit.

The inner bit can be advanced in front of the casing bit to act as a pilot bit for the casing string or it can be retracted inside the casing crown reaming bit to better contain flushing inside the casing.

In combination with a DTH system on the inner drill string, a Rotary-Rotary system is able to achieve deeper depths compared to drifter (top hammer) based systems.

Double casing drill systems are a preferred method for drilling straight, deep holes. These systems offer the driller a high level of flexibility and control to deal with varying ground condition.

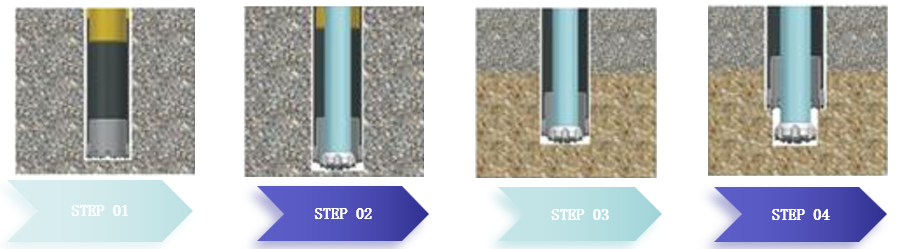

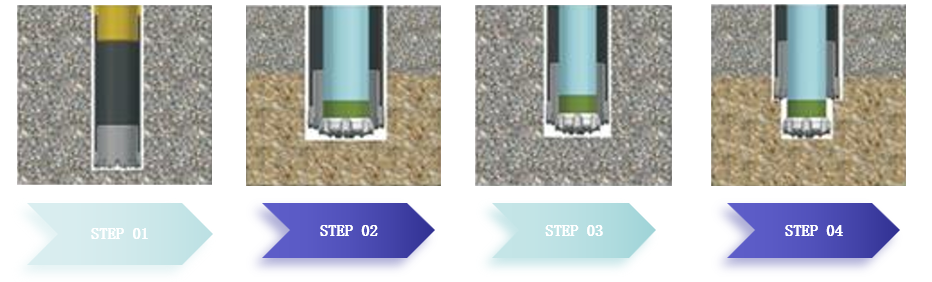

Top hammer type drilling inside the casing | DTH hammer type drilling inside the casing |

|

|

Performance:

1. The product surface is hardened, with longer service life and wear resistance

2. The structure is optimized and reasonable

3. Superior performance, stable operation and high efficiency

Application:

DTH & Top Hammer type Double casing drilling tools is Suitable for geothermal drill for grouting, sampling, water well drill, foundation drill etc.

Working principle:( Top hammer type)

1. Firstly, connect the crown opener bit and the outer casing tube, the drifter of the rig impacts the advancing of the outer casing tube, until finish the completion of the first tube.

2. The inner opener bit is connected with the drill rod, the drifter alongside the bore of the outer tube, until finish the completion of the first tube.

3. Connect the drill rod and the tube, the drifter of the rig push forward the external casing tube altogether with the drill rod until the external casing tube is reached the desired depth.

4. No need to add any casing tube in the bedrock, only apply with the drill rod to push down to the desired depth.

Working principle:( DTH type)

1. Firstly, connect the crown opener bit and the external casing tube, the drifter of the rig impacts the advancing of the external casing tube, until finish the completion of the first tube.

2. The hammer connected with the drill rod, the hammer drill alongside the external casing tube until finish the completion of the first tube.

3. Connect the drill rod with the casing tube, the drifter of the rig push forward the external casing tube, the hammer impacts the drill rod forward until the external casing tube is reached the desired depth.

4. Drilling continues to the desired depth in the bedrock using a conventional drilling tools.

Specification:

DTH and Top Hammer type Double casing drilling tools

序号 | Outer Dia. (mm) | Reamed Dia. (mm) | Inner Dia. (mm) | Thread (mm) | Drill Rod (mm) | Drill Bit Dia. (mm) | Thread |

1 | 118 | 125 | 88 | 104.5 | 76 | 83 | R56 |

2 | 133 | 140 | 108 | 122 | 76 | 102 | R56 |

3 | 146 | 152 | 120 | 134 | 89 | 116 | R78 |

4 | 168 | 172 | 133 | 146.5 | 114 | 128 | R83 |

5 | 216 | 225 | 178 | 203 | 114 | 165 | R102 |

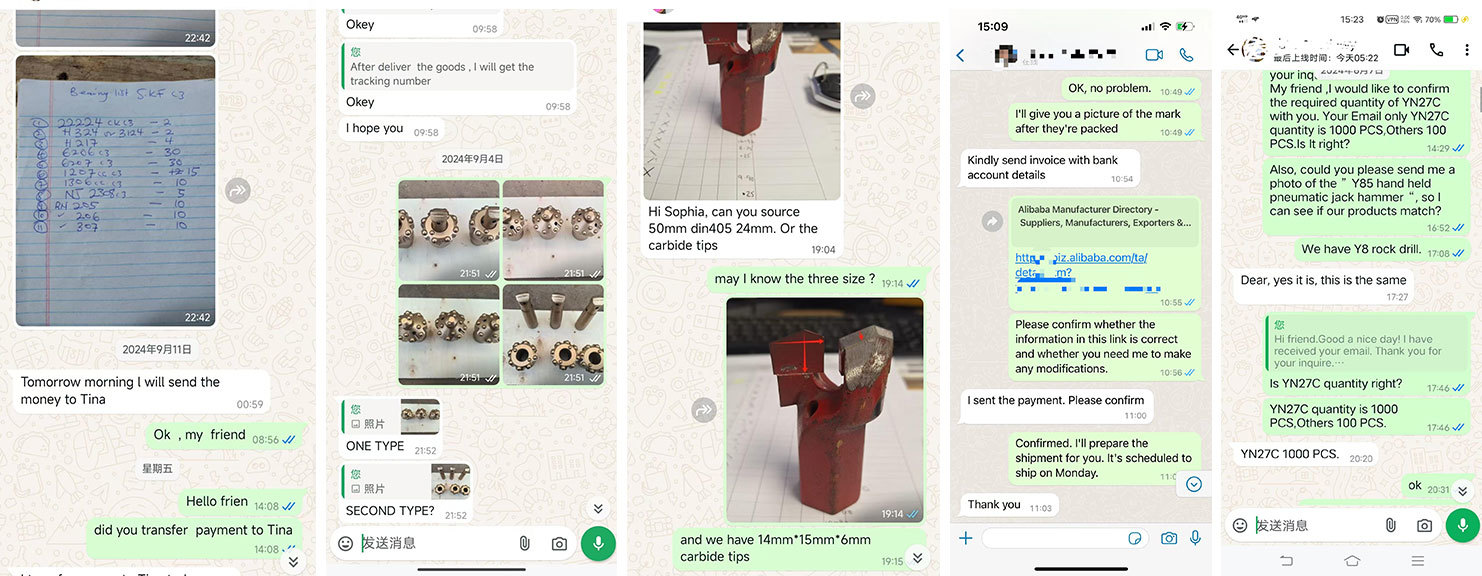

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

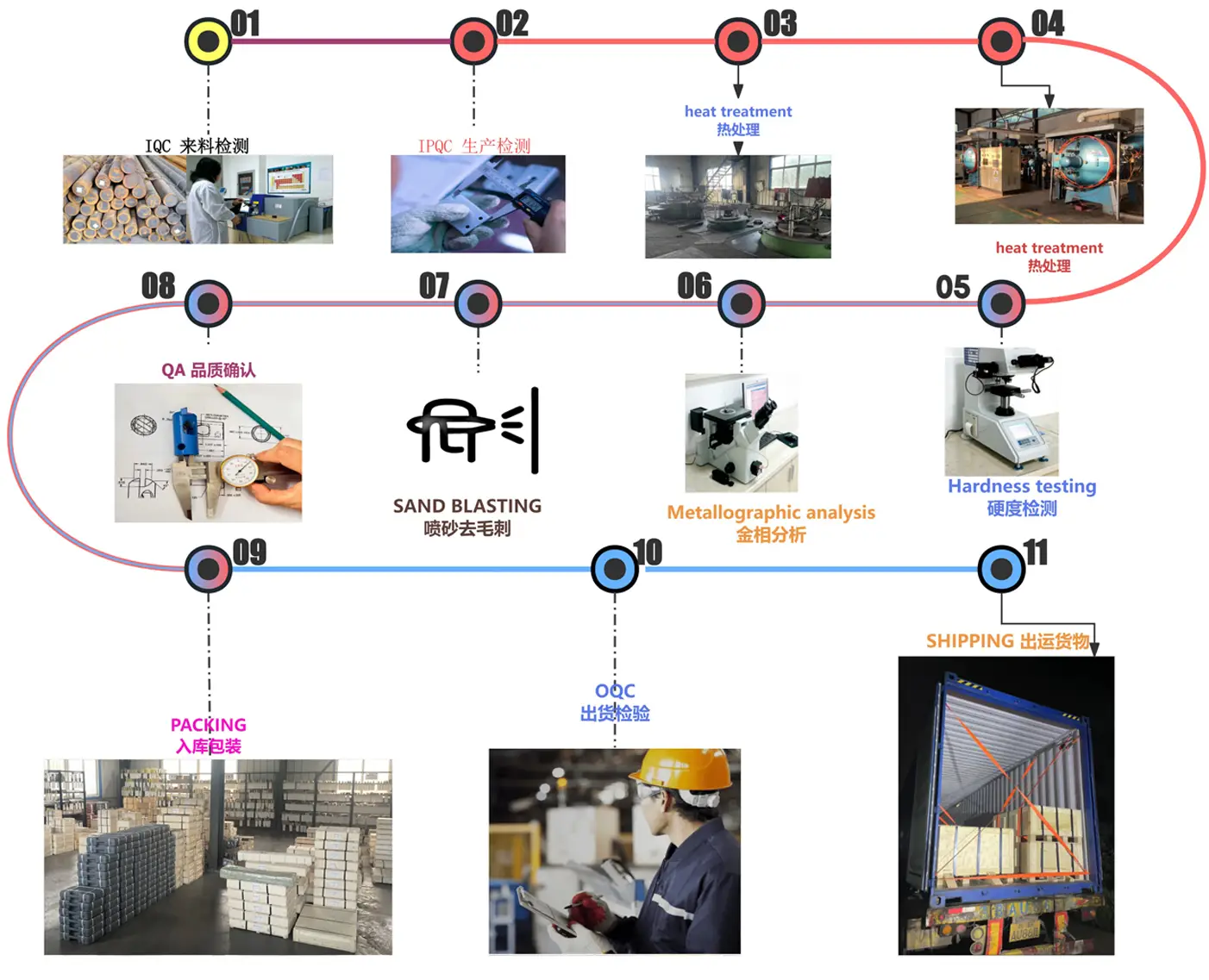

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE