Forepoling Ring Bit System (Tube Umbrella)

Ring bit diameter:71mm

Tungsten carbide size:3*11mm,3*11mm

Weight:3.4kg

Pilot bit diameter:100mm

Tungsten carbide size:6*11mm

Weight:2.05kg

Application: suite 89mm pipe

Key words:

Rock Bolt

Product Details

Description

One of the most important aspects of tunnelling in soft grounds is to reduce any possible

adverse environmental impact.The umbrella arch method is one of the most common ground pre-supporting techniques used in tunnelling.

In implementing the method,Process of drilling and application are made together on self drilling systems. Self drilling system is made ring bits and pilot bits. Ring bits are welded end of forepiling

pipe. The rods that end have pilot bits are passed inside to forepoling pipe and locked. Process of locking are made to direction of drilling and started drilling. The rod is turned opposite direction and opened lock after drilling. Through this process the rod is pulled reverse but forepoling pipe and ring bit stays inside the hole.

straightness is vital in both design as well as economical aspects.Drill very straight holes thanks to The Ring bit with pilot bit and smooth drilling.

Performance

HLDRILL Ring bit with pilot bit main advantage: straight holes,Economical, durable,

Application

The pilot bit and ring bit is used in tunnelling pre-supporting .

Pilot bit which drills the center part of the hole and transfers the impact energy to the ring bit .

Ring bit set, which is an integrated ring bit and casing shoe, welded to the front of first pipe, known as the starter pipe.

The ring bit, which is connected to the pilot bit through locking mechanism, drills the void needed to advance the pipe into the ground simultaneous to drilling.

Specification

Pipe Roof System

products | Ring Bit Ø | Pilot Bit Ø | Suite Pipe Ø | |||

mm | inch | mm | inch | mm | inch | |

| 89 | 3″ 1/2 | 59 | 2″ 1/4 | 76,1 | 3″ |

100 | 3″ 7/8 | 71 | 2″ 7/8 | 88,9 | 3 1/2″ | |

118 | 4″ 5/8 | 80 | 3″ 1/8 | 101,6 | 4″ | |

129 | 5″ 1/8 | 89 | 3″ 1/2 | 114,3 | 4 1/2″ | |

156 | 6″ 1/8 | 116 | 4 ″1/2 | 139,7 | 5 1/2″ | |

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

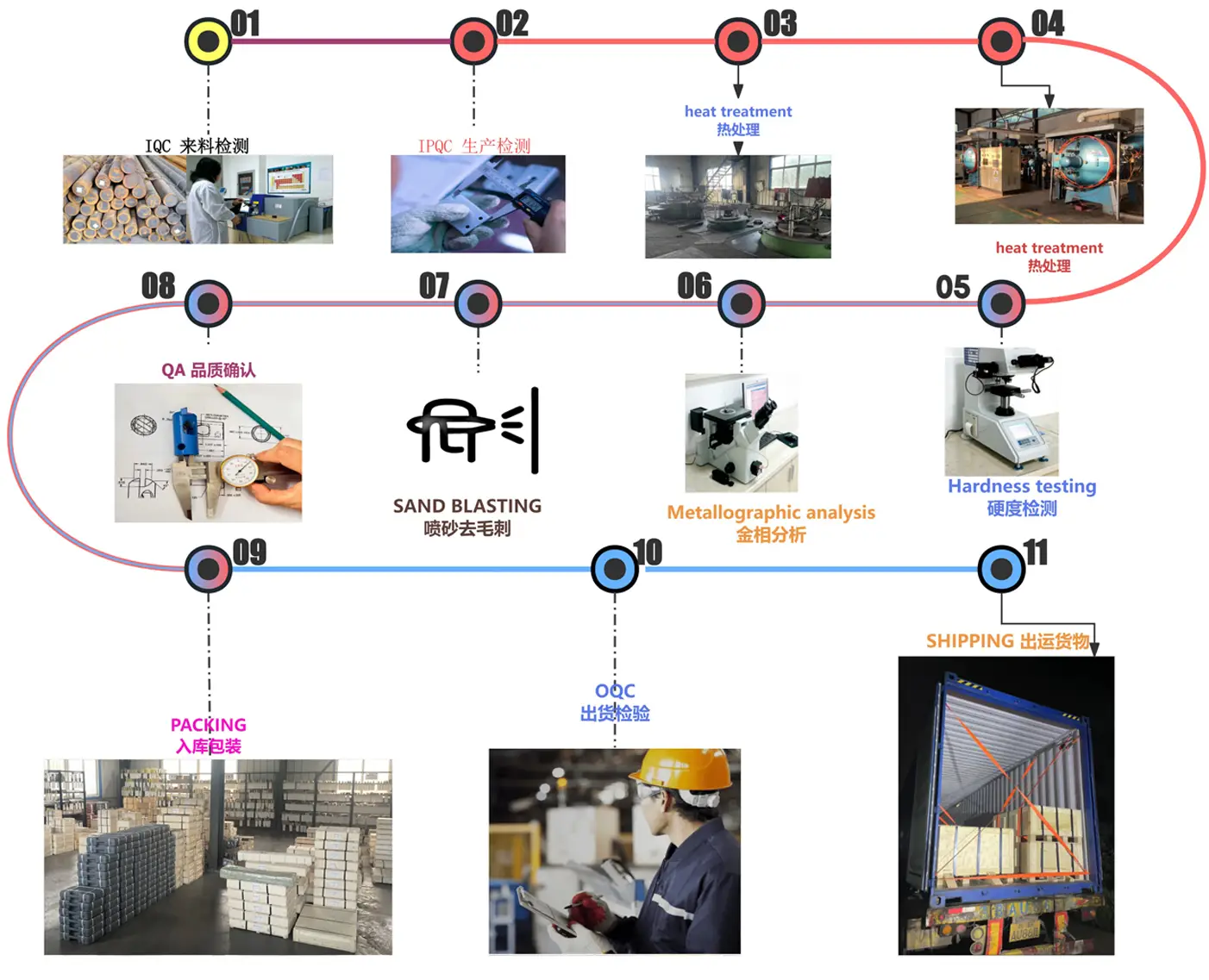

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE