Furnace tapping drill bits

Product type: slugger

Diameter:80 mm up to 120 mm.

Material:42CrMo

Process:Heat Treatment

Key words:

Furnace Tapping Tools

Product Details

Description

HENGLONG Drill Furnace tapping drill bit with high quality which ensure the efficiency and service life of your blast furnace and ferro-alloy applicaton equipment. HLDRILL select special materials and manufacturing processes to suit the machines performance and thereby enhance stability and reliability. Our individually selected material qualities ensure low wear and ultimately have a direct impact on the economic efficiency of the whole plant.

Furnace tapping drill bit shape and material (carbide or heat resistant Cr-Ni alloy tips) are important. The ability to retain a sharp cutting edge to cut, rather than hammer, through the tap hole mass, is important with the bit cutting face presented to a debris and dust free face to drill. Drill bit diameter is usually controlled within a range of 33 mm to 65 mm. Where hammering is considered important, an inside bit face that is totally flat, to maximize transmission of impact energy coupled with transition from spherical to semi-spherical carbide shapes is used. Air scavenging is typically used to achieve a cleared hole, additionally providing some cooling of the drill bit to help prolong its life.

Furnace tapping drill bits include button bit and cross bit with soft tap hole clay and no inclusion of slag or iron.Threaded Drill rods with threaded the whole steel drill bits, The drill bit makes a clean hole with a constant diameter from beginning to end. The Furnace tapping drill bit is made from wear resistant cast steel and interchangeable with different drill rods.we can offer R28,R32,T38 ,t45 thread tap etc.

Furnace tapping drill bits from 32mm-152mm,coupling,adaptor and Rod etc.

blast furnace tapping hole drilling tools.

1) Drill rod together with the whole steel drill bit by welding connecting

This tools are simple produced and have within our product range the most

competitive price.It can be used for drilling of short and not difficult to drill

tapping holes with soft tap hole clay and no inclusion of slag or iron.

2)Threaded Drill rods with threaded the whole steel drill bits

The drill bit makes a clean hole with a constant diameter from beginning to end.

The bit is made from wear resistant cast steel and interchangeable with different

Performance

Premium designs and steel and premium tungsten carbide insert grade T6 supplied by HENGLONG Offers industry-leading strength and penetration rates for more productivity,Excellent straightness and hole clean quality,Get max.drilling performance for rock drills with long life to save up fuel cost rate.

HENGLONG WORKSHOP and Process of manufacturing

Application

It was widely used in big steel mill for Deliver liquid steel specially from blast furnace.

Specification

|

e. g. |

Racer |

Cutter |

Slitter |

Miller |

Slugger |

|

Type |

RC |

CT |

SL |

ML |

SG |

|

Diameter |

40 mm up to 75 mm |

40 mm up to 75 mm |

40 mm up to 75 mm |

40 mm up to 80 mm |

80 mm up to 120 mm |

|

Thread |

R32 |

R32 |

R32 |

R32 |

R32 |

|

photo |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

e. g. |

Slugger HM |

Blade |

Graver HM |

Starter Bit |

Taphole Reamer |

|

Type |

SGHM |

BD |

GVHM |

SB |

TR |

|

Diameter |

45 mm up to 120 mm |

45 mm up to 80 mm |

40 mm up to 80 mm |

80mm |

210 mm up to 300 mm |

|

Thread |

R32 |

R32 |

R32 |

R32/R38 |

R32 left |

|

photo |

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

||

|

|

|

|

|

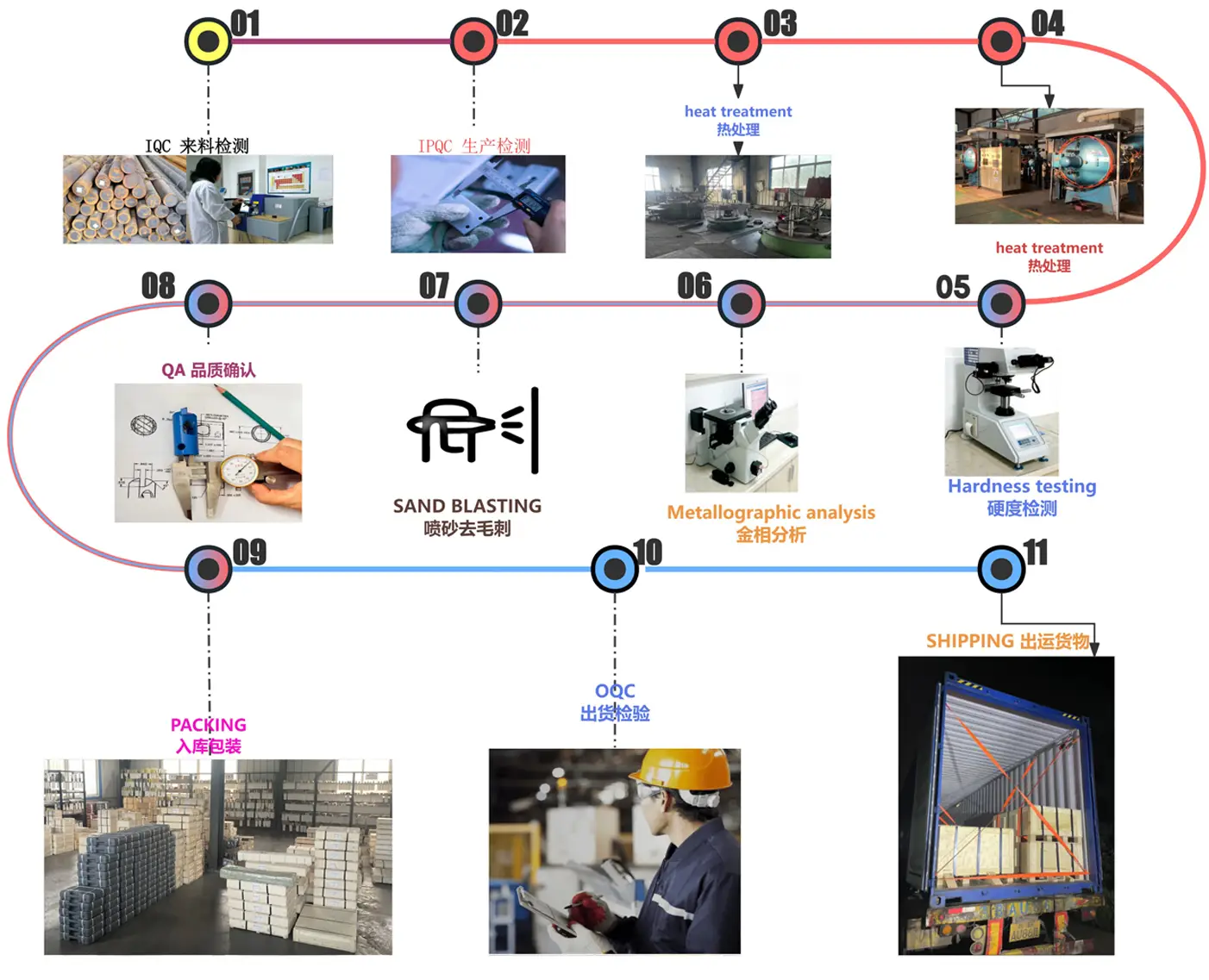

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE