Low air pressure DTH bits

Dia.:90mm

Face shape:Flat face

Button shape:ballistic

Button size×No.:2×12mm,2×13mm,6×14mm

Weight:3.69kg

Material:Carbon Steel

Key words:

DTH hammer tools

Product Details

Description

HENGLONG CIR90 low air pressure DTH bits:Fabricated with high-strength alloy for durability and wear resistance.Unique design optimizes drilling efficiency and reduces energy consumption.

Advanced cooling system prevents overheating, enhancing stability and lifespan.

Easy to install and maintain, reducing overall costs.

HENGLONG CIR90 low air pressure DTH bits Face Shape Selection:

|

Face shape |

Use condition |

|

|

|

Concave Face |

the all-round application bit face specifically for medium hard and homogenerous rock formations.Good hole deviation control and good flushing capacity. |

|

|

Convex Face |

For high penetration rates in soft to medium-hard with low |

|

|

Flat Face |

This kind of face shape is suitable for hard to very hard and abrasive rock formations in applications with high air pressures.Good penetration rates an resistance to steel wash. |

HENGLONG CIR90 low air pressure DTH bits button Shape Selection:

|

Button shape |

Use condition |

|

|

|

Domed/Round Button |

Domed/Round Button are usually used as gauge buttons of DTH Bits,suitable for very abrasive and very hard formations. |

|

|

Parabolic/Semi-Ballistic Button |

Parabolic Buttons are usually used as gauge buttons and front buttons of DTH Bits,suitable for medium abrasive and hard formations. |

|

|

Ballistic Button |

Ballistic Bultons are usually used as front buttons of DTH Bits,suit-able for medium abrasive and medium hard formations.They can alsobe used as gauge buttons if the rock is soft |

|

|

Sharp Button |

Sharp Buttons are usually used as front buttons of DTH Bits for softformations where fast penetration rates are possible and button bre-akage is minimal, |

|

|

Flat Button |

Flat Buttons are usually used as protection buttons to reduce wear onrubbing surfaces of DTH Bits. |

Performance

1. Strict supplier quality management, the use of high-quality steel and hard alloy, warhead service life is long.

2. Advanced high-speed machining center and automatic processing equipment, product reliability and stability first-class.

3. The head shape distribution is scientific and diverse, which can complete the construction work of the whole terrain and all directions.

4. Manufacturers direct sales, according to your actual work situation to provide you with a more suitable bit structure.

Applications

Widely used in geological exploration, mineral resource development, and engineering foundation construction, especially in low-pressure environments. Ideal for various drilling projects requiring reliable and efficient performance.

Specification

|

CIR50 |

Dia.(mm) |

Gauge button |

Weight(Kg) |

Part NO. |

|

Ballistic button/Flat face

|

50 |

3×φ10 |

0.54 |

CIR50-50BF |

|

CIR60 |

Dia.(mm) |

Gauge button |

Weight(Kg) |

Part NO. |

|

Ballistic button/Flat face

|

60 |

3×φ12 |

1.1 |

CIR60-60BF |

|

CIR65 |

Dia.(mm) |

Gauge button |

Weight(Kg) |

Part NO. |

|

Ballistic button/Flat face

|

65 |

4×φ12 |

1.42 |

CIR65-65BF |

|

CIR70 |

Dia.(mm) |

Gauge button |

Weight(Kg) |

Part NO. |

|

Ballistic button/Flat face

|

76 |

5×φ12 |

2.18 |

CIR76-76BF |

|

CIR90 |

Dia.(mm) |

Gauge button |

Weight(Kg) |

Part NO. |

|

Ballistic button/Convex face

|

90 |

6×φ14 |

3.69 |

CIR90-90BC |

|

100 |

6×φ14 |

4.25 |

CIR90-100BC |

|

|

110 |

6×φ14 |

4.92 |

CIR90-110BC |

|

|

120 |

6×φ14 |

5.52 |

CIR90-120BC |

|

|

130 |

7×φ14 |

6.56 |

CIR90-130BC |

|

|

CIR110 |

Dia.(mm) |

Gauge button |

Weight(Kg) |

Part NO. |

|

Ballistic button/Convex face

|

110 |

6×φ14 |

5.86 |

CIR110-110BC |

|

120 |

6×φ14 |

5.89 |

CIR110-120BC |

|

|

130 |

7×φ14 |

7.59 |

CIR110-130BC |

|

|

140 |

8×φ14 |

8.47 |

CIR110-140BC |

|

|

150 |

8×φ14 |

9.47 |

CIR110-150BC |

|

|

170 |

9×φ14 |

11.44 |

CIR110-170BC |

|

|

Ballistic button/Flat face |

110 |

6×014 |

5.86 |

CIR110-110BF |

|

120 |

6×φ14 |

5.89 |

CIR110-120BF |

|

|

130 |

7×φ14 |

7.59 |

CIR110-130BF |

|

|

140 |

8×φ14 |

8.47 |

CIR110-140BF |

|

|

150 |

8×φ14 |

9.47 |

CIR110-150BF |

|

|

170 |

9×φ14 |

11.44 |

CIR110-170BF |

|

|

CIR130(Shank 65mm and 76mm) |

Dia.(mm) |

Gauge button |

Weight(Kg) |

Part NO. |

|

Ballistic button/Convex face |

130 |

7×φ14 |

7.59 |

CIR130-130BC |

|

140 |

8×φ14 |

8.47 |

CIR130-140BC |

|

|

150 |

8×φ14 |

9.47 |

CIR130-150BC |

|

|

170 |

9×φ14 |

11.44 |

CIR130-170BC |

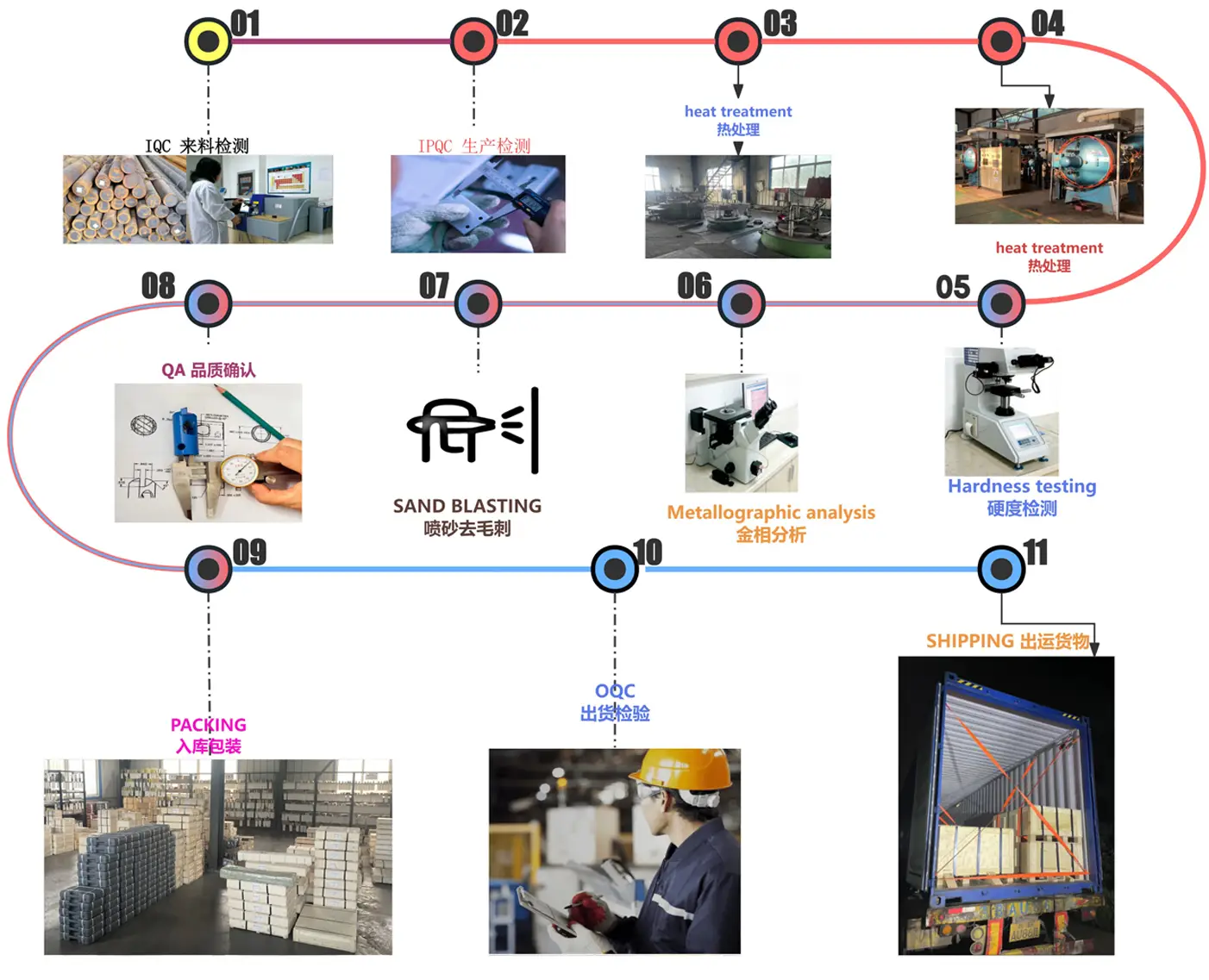

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE