Recovery taps according to their shape into straight flute taps, spiral flute taps and spiral point taps (tip tap).Straight flute tap is easily processed, accuracy is slightly lower, larger production.Generally used lathe, drilling and tapping machine screw machining, the cutting speed is slower. Spiral flute taps are used for CNC machining centers with a blind hole drilling,processing speed, high precision,chip better, the neutral good. Spiral Point Taps Front tolerance cut slots for through-hole machining.

HLDRILL provides now mostly coated tap tap, tap than uncoated life and cutting performance has greatly improved. Designed to tap the cutting diameter ranging from load distribution

reasonable, processing of high quality, but the manufacturing cost is also high. Trapezoidal thread taps often use different diameters design.

The taper tap is run into a fish and rotated to cut enough threads to permit the fish to be pulled & recovered.Taper tap is a special tool cutting threads and fishing internally in dropped objects such as tubing, drill -pipe,wash-over pipe. packer. water flow allocator. down-hole production allocator.The tool is especially a great success in catch of objects accompanied with couplings. The taper tap can offer different fishing operations when equipped with RH thread or LH thread drill

pipes and other tools.

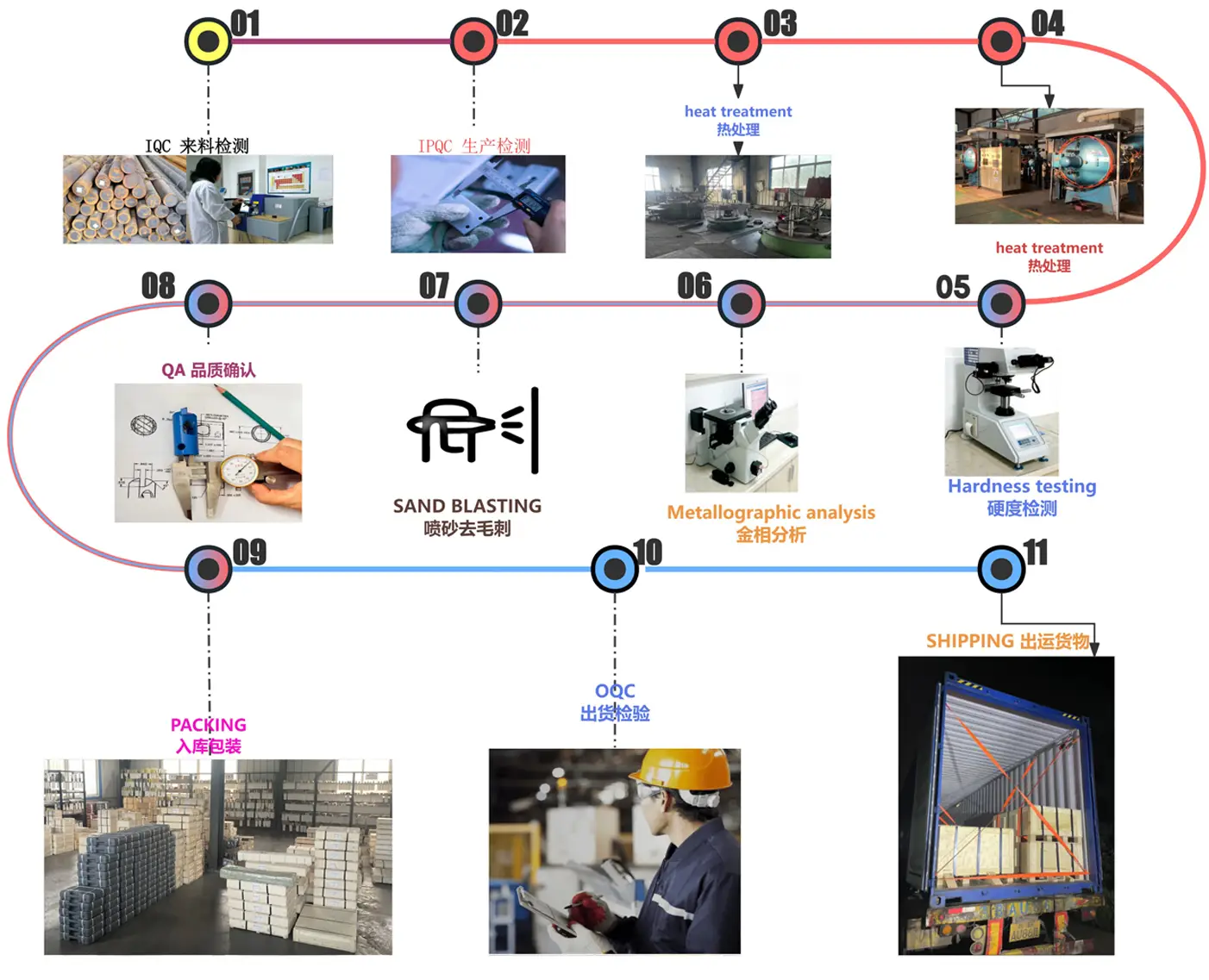

Performance

easy use, and reliable performance.

Application

Recovery pike is used for pick up drill bit drop into prehole, front section can be changed as per top hammer drill bit, and down the hole drill bit

Specification

Package