Rock Drill Rubber Hose

Capability:Rubber Air Hose

Color:Black, Blue, Red, Orange

Inner Tube:Nr,SBR,NBR,EPDM

Reinforcement: High Tensile Polyester Fiber Braided

Cover Tube:SBR&EPDM&NBR

Construction: Tube: NR& SBR synthetic rubber.

Reinforcement: High tensile polyester fiber braided.

Cover: NR & SBR synthetic rubber.

Temperature: -30ºC - +80ºC

Color: Black, Red, Yellow, Blue, Green, Orange, etc.

Standard length: 50m, 100m.

Key words:

Rock Drill Hose

Product Details

Description

NR/SBR is a compound consisting of natural and styrene-butadiene rubber and is the most widely used rubber compound for a wide range of the simplest applications, thanks in part to the excellent mechanical and dynamic properties of this material.

Only moderate resistance to numerous chemicals as well as alkalis and acids can be assumed. NR/SBR is also unsatisfactory in terms of its ageing resistance and resistance to ozone and UV light. The material is also not recommended with regard to fuels or cleaning agents containing solvents.

NR/SBR seals can be used for hydraulic and pneumatic applications where high mechanical wear due to friction is to be expected. The interior of buildings or housings as well as UV-protected outdoor areas can be highlighted as a further area of application. Furthermore, the material is suitable as wear protection, abrasion protection as well as impact protection.

We are well designed for providing different types of rock drill hose for according to customer requirement. The rock drill hose manufactured by experienced staff and made up of high quality of material. These are available in different size and specification so easily meets different drilling requirement.

The rock drill hose pipes have various features with different types, model numbers, size, working pressure, burst pressure and temperature range. Our rock drill rubber hose are recommended for various places weather in open miles and quarries. We also engage in air rock drill hose are demanded where heavy duty and heavy pressure is required. We also deals in hydraulic rock drill hose of superior quality.

Performance

High elasticity

High cold flexibility

High tensile strength

High abrasion resistance

Only moderate resistance to numerous chemicals as well as alkalis and acids can be assumed. NR/SBR is also unsatisfactory in terms of its ageing resistance and resistance to ozone and UV light. The material is also not recommended with regard to fuels or cleaning agents containing solvents.

Applications

Rock drill rubber hose is Mainly used for conveying of air, insert gas and water in mining, construction, engineering, shipbuilding, steel production etc.

Specification

|

Inner Diameter |

Outer Diameter |

Working Pressure |

Burst Pressure |

Length |

Measurement |

Weight |

|||

|

inch |

mm |

mm |

bar |

psi |

bar |

psi |

m |

cbm/roll |

kg/m |

|

3/16” |

5 |

12 |

20 |

300 |

60 |

900 |

100 |

0 |

0 |

|

1/4" |

6 |

13 |

20 |

300 |

60 |

900 |

100 |

0 |

0 |

|

5/16” |

8 |

15 |

20 |

300 |

60 |

900 |

100 |

0 |

0 |

|

3/8” |

10 |

17 |

20 |

300 |

60 |

900 |

100 |

0 |

0 |

|

1/2" |

13 |

21 |

20 |

300 |

60 |

900 |

100 |

0 |

0 |

|

5/8" |

16 |

24 |

20 |

300 |

60 |

900 |

50 |

0 |

0 |

|

3/4” |

19 |

29 |

20 |

300 |

60 |

900 |

50 |

0 |

1 |

|

1"(1b) |

25 |

36 |

12 |

180 |

36 |

540 |

50 |

0 |

1 |

|

1"(2b) |

25 |

37 |

20 |

300 |

60 |

900 |

50 |

0 |

1 |

|

1-1/4” |

32 |

44 |

10 |

150 |

30 |

450 |

50 |

0 |

1 |

|

1-1/2" |

38 |

51 |

10 |

150 |

30 |

450 |

50 |

0 |

2 |

|

2” |

51 |

65 |

10 |

150 |

30 |

450 |

20 |

0 |

2 |

HENGLONG workshop and Process of manufacturing

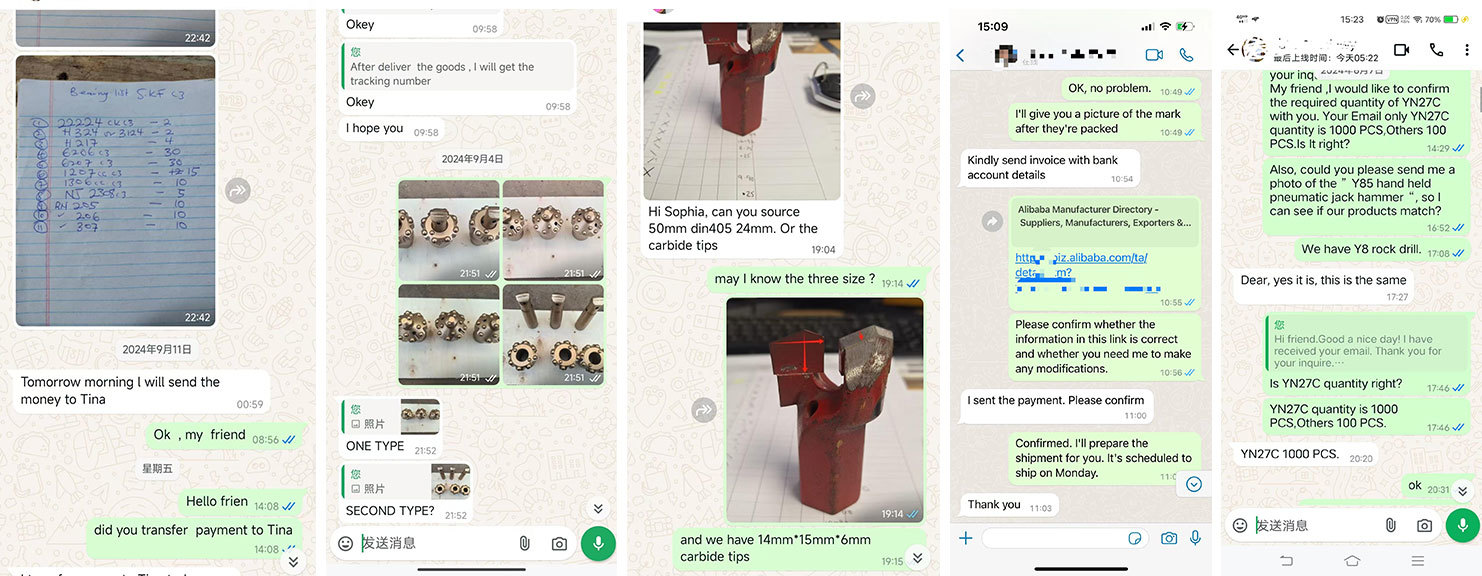

Packing and shipping

Factory

Customer visit

Production

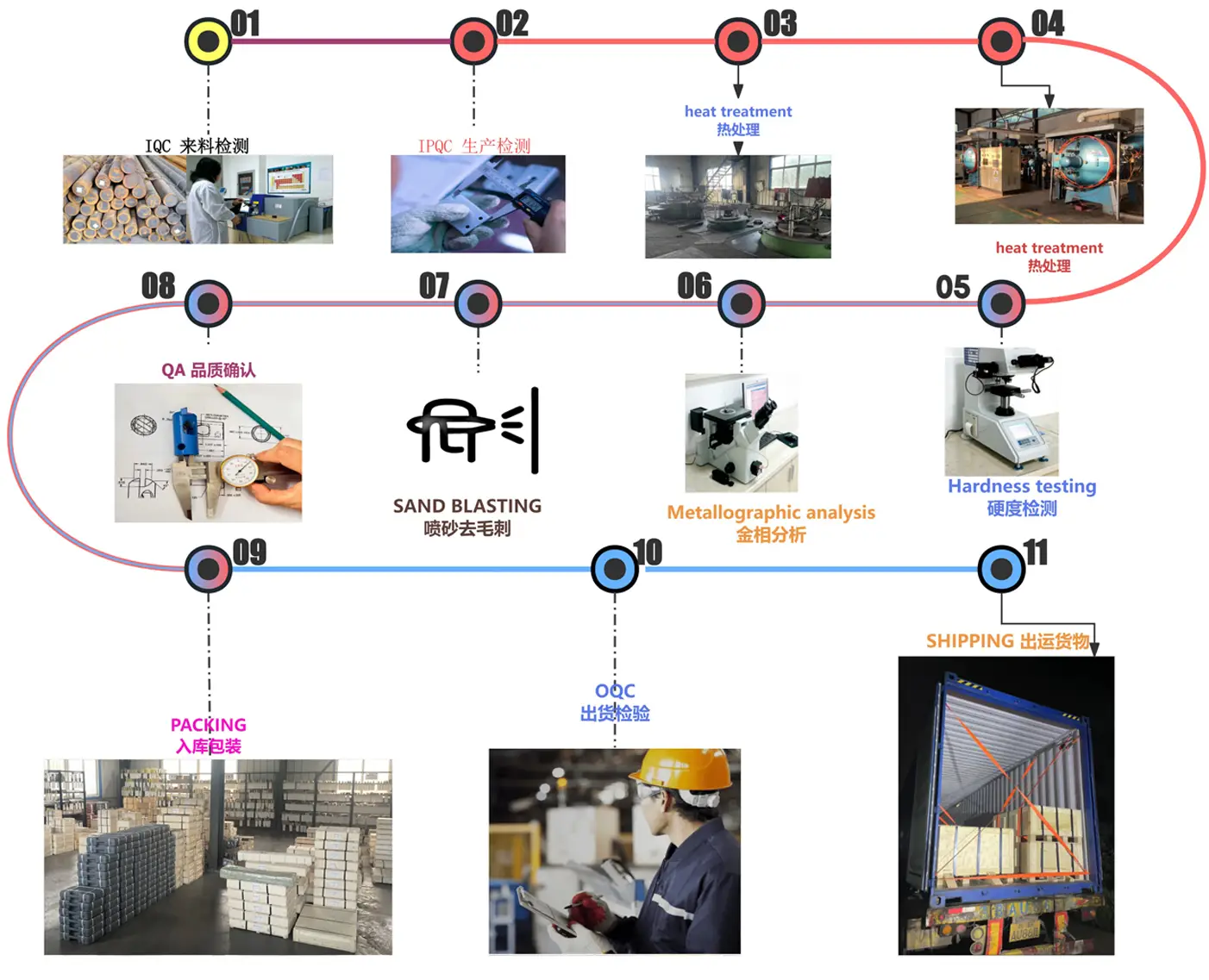

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE