Short skirt button bits

Q7-32-1122-50 Taper Button Bits

Diameter: 32mm

Carbide size :2*7mm 5*7mm

Steel materials : 50R61

Carbide grade : YK05

Carbide shape: ballistic

Taper degree:11°

Key words:

Tapered Button Bit

Product Details

Description

HENGLONG drill can producce button bits grinding machine and diamond grinding cups and grinding wheels for blunt carbide button sharpening for extension drilling life by 20-30%.Never have to persevere with blunt drill heads again.The height of the short skirt button bits are generally 50-55mm

HENGLONG drill taper button bits as small hole bits are different with thread button bits as long hole bits to use taper match with bits with rods to be used for air leg or hand held jack hammer drillers in quarrying,and mining. to match YT24, YT28, YT29A air pusher rock drills. such as Peru, Chile, Colombia etc. most of main size as follow :

Carbide code : T6 grade ( world No.1 ) Designed for underground mining to match YT24, YT28, YT29A air pusher rock drills in Peru, Chile, Colombia,UK.

Details Form

|

SHORT SKIRT BUTTON BITS |

|||||||||

|

Drill bit |

Diameter |

NO.×button diameter |

Flushing hole |

Weight (kg) |

HENGLONG P/N |

||||

|

mm |

inch |

Center |

Gauge |

Angle |

Front |

Side |

|||

|

Button bit ,Short skirt |

32 |

1 1/4 |

1×8 |

3×8 |

35° |

1 |

2 |

0.24 |

1431-321122-18/38-45-51 |

|

32 |

1 1/4 |

2×7 |

5×7 |

40° |

1 |

1 |

0.24 |

1431-321122-27/57-45-51 |

|

|

33 |

1 19/64 |

2×7 |

4×7 |

40° |

1 |

1 |

0.25 |

1431-331122-27/47-45-51 |

|

|

34 |

1 11/32 |

2×7 |

4×7 |

40° |

1 |

1 |

0.29 |

1431-341122-27/47-45-51 |

|

|

35 |

1 3/8 |

2×7 |

5×7 |

35° |

1 |

1 |

0.33 |

1431-351122-27/57-45-51 |

|

|

35 |

1 3/8 |

2×7 |

5×8 |

35° |

1 |

1 |

0.33 |

1431-351122-27/58-45-51 |

|

|

36 |

1 27/64 |

1×8 |

3×9 |

40° |

1 |

1 |

0.36 |

1431-361122-18/39-45-51 |

|

|

36 |

1 27/64 |

2×7 |

4×7 |

40° |

1 |

1 |

0.36 |

1431-361122-27/47-45-51 |

|

|

36 |

1 27/64 |

2×7 |

5×8 |

35° |

1 |

1 |

0.36 |

1431-361122-27/58-45-51 |

|

|

38 |

1 1/2 |

1×9 |

3×9 |

40° |

1 |

1 |

0.39 |

1431-381122-19/39-45-51 |

|

|

38 |

1 1/2 |

2×8 |

3×9 |

40° |

1 |

1 |

0.39 |

1431-381122-28/39-45-51 |

|

|

38 |

1 1/2 |

2×7 |

5×8 |

35° |

1 |

1 |

0.39 |

1431-381122-27/58-45-51 |

|

|

38 |

1 1/2 |

2×7 |

5×9 |

35° |

1 |

1 |

0.39 |

1431-381122-27/59-45-51 |

|

|

40 |

1 37/64 |

1×9 |

3×9 |

40° |

1 |

1 |

0.4 |

1431-401122-19/39-45-51 |

|

|

40 |

1 37/64 |

2×8 |

3×9 |

40° |

1 |

1 |

0.4 |

1431-401122-28/39-45-51 |

|

|

40 |

1 37/64 |

2×9 |

3×9 |

40° |

1 |

2 |

0.4 |

1431-401122-29/39-45-51 |

|

|

40 |

1 37/64 |

2×7 |

5×9 |

35° |

1 |

1 |

0.4 |

1431-401122-27/59-45-51 |

|

|

40 |

1 37/64 |

2×8 |

5×9 |

35° |

1 |

1 |

0.4 |

1431-401122-28/59-45-51 |

|

|

41 |

1 5/8 |

2×7 |

5×9 |

35° |

1 |

1 |

0.41 |

1431-411122-27/59-45-51 |

|

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

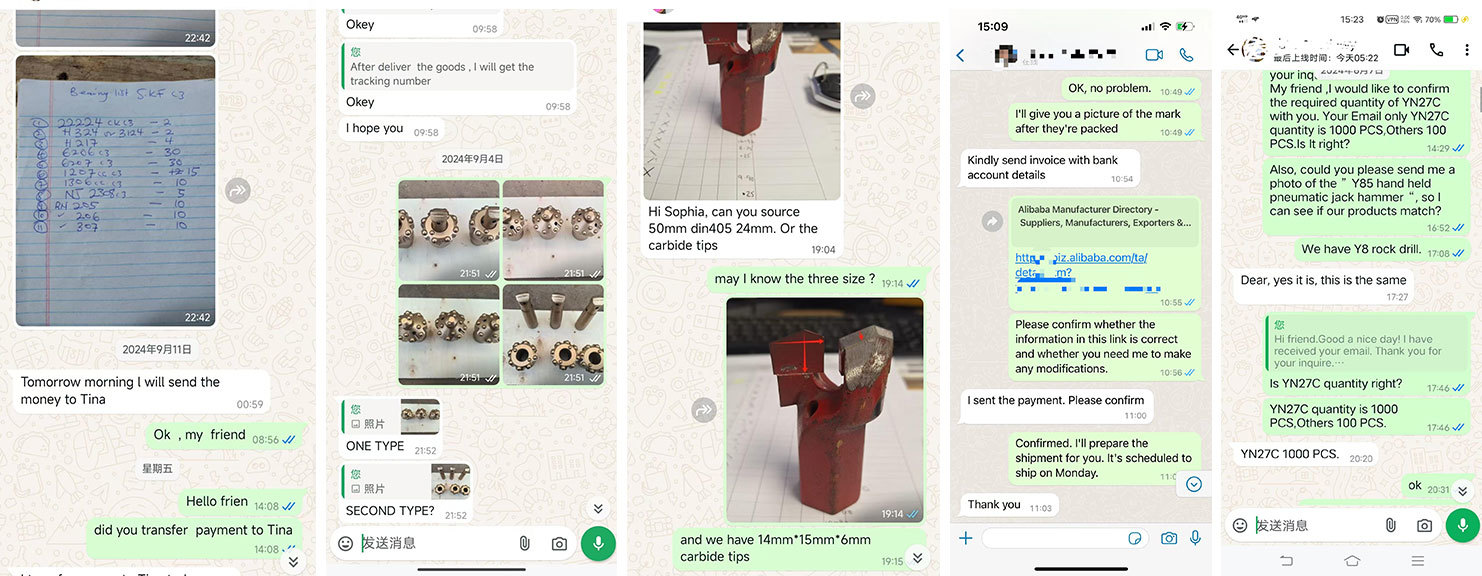

Customer visit

Production

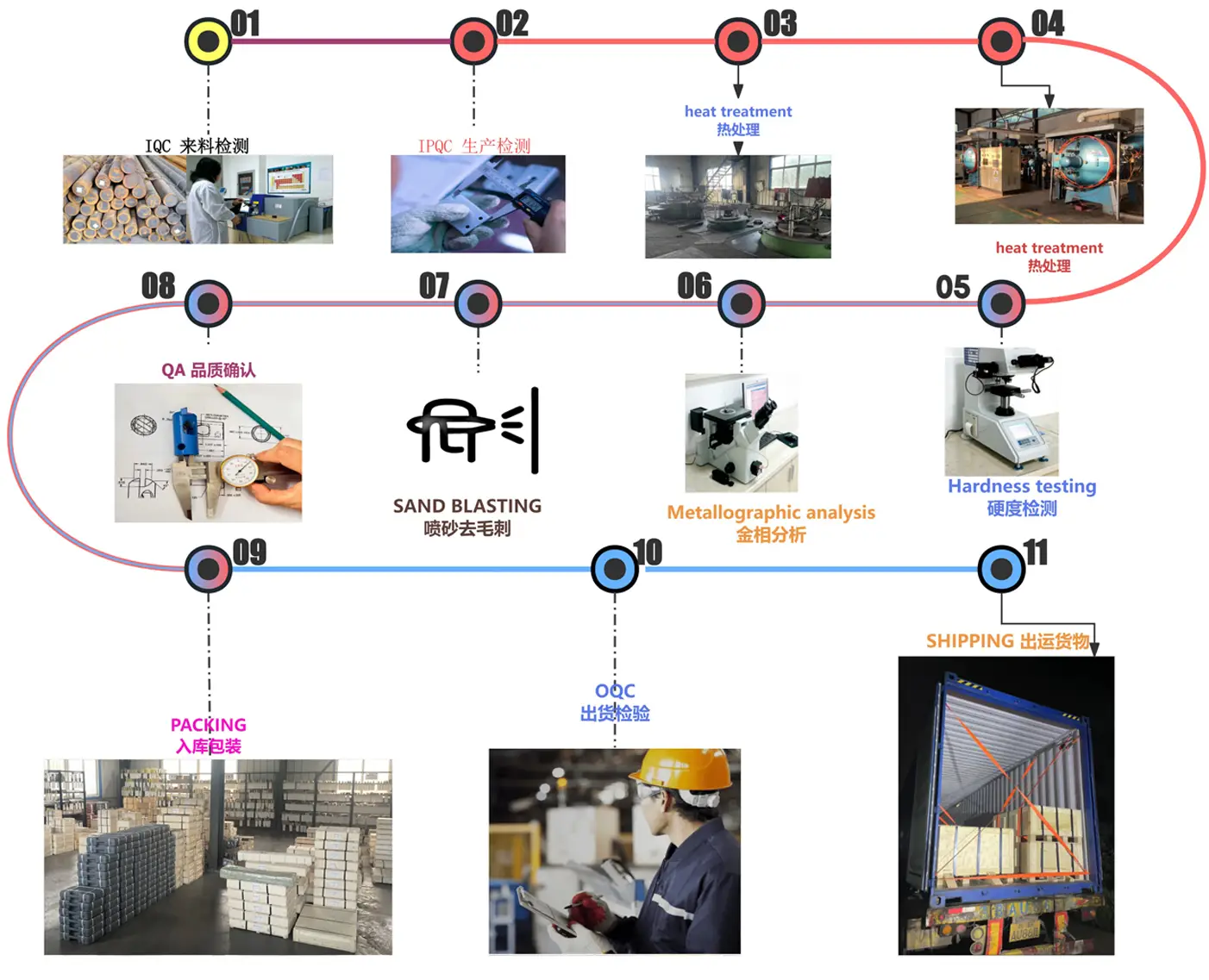

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE