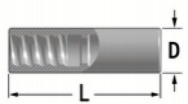

T45 coupling sleeves

Thread:T45

Length:210mm

Weight:3.0kg

Material:23CrNi3Mo

Key words:

Coupling

Product Details

Description

Coupling sleeves, other name is Coupling, when using rock drills with male shank adapters and a conventional drifter rod, a coupling is required to join the adapter to the rod, ensuring the ends touch for efficient energy transmission. Couplings are also used to connect several rods to each other in the same way. Couplings have a middle stop to prevent over-threading on to the drill rod. We can manufactures semi-bridge, full bridge coupling sleeves for the percussive tools.

Semi-Bridge Coupling sleeve

Small non-threaded bridge in the center,Steel cannot thread past bridge area

Smaller diameter steel end portions fit together in the centre bridge area of the coupling

Semi-bridged couplings are most suited to high torque machines

Most rope and T threaded couplings are semi-bridged

Full-Bridge Coupling sleeve

Eliminates the potential for the coupling to creep along the threaded joints

Typically used in surface applications

Better uncoupling characteristics and tend to maintain tighter joints

Less chance of jamming

Performance

High strength chromium-molybdenum steel with high fatigue strength and excellent wear resistance

Application

Used in benching and long hole drilling.

Details Form

|

T45 coupling sleeves |

|||||||

|

Coupling sleeves |

length |

Outer dia. |

thread

|

Weight (kg)

|

|

||

|

|

mm |

foot |

mm |

inch |

|

||

|

210 |

8 1/4 |

63 |

2 33/64 |

T45 |

3.0 |

31-T45-63-210-23 |

|

|

210 |

8 1/4 |

66 |

2 37/64 |

T45 |

3.3 |

31-T45-66-210-23 |

|

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

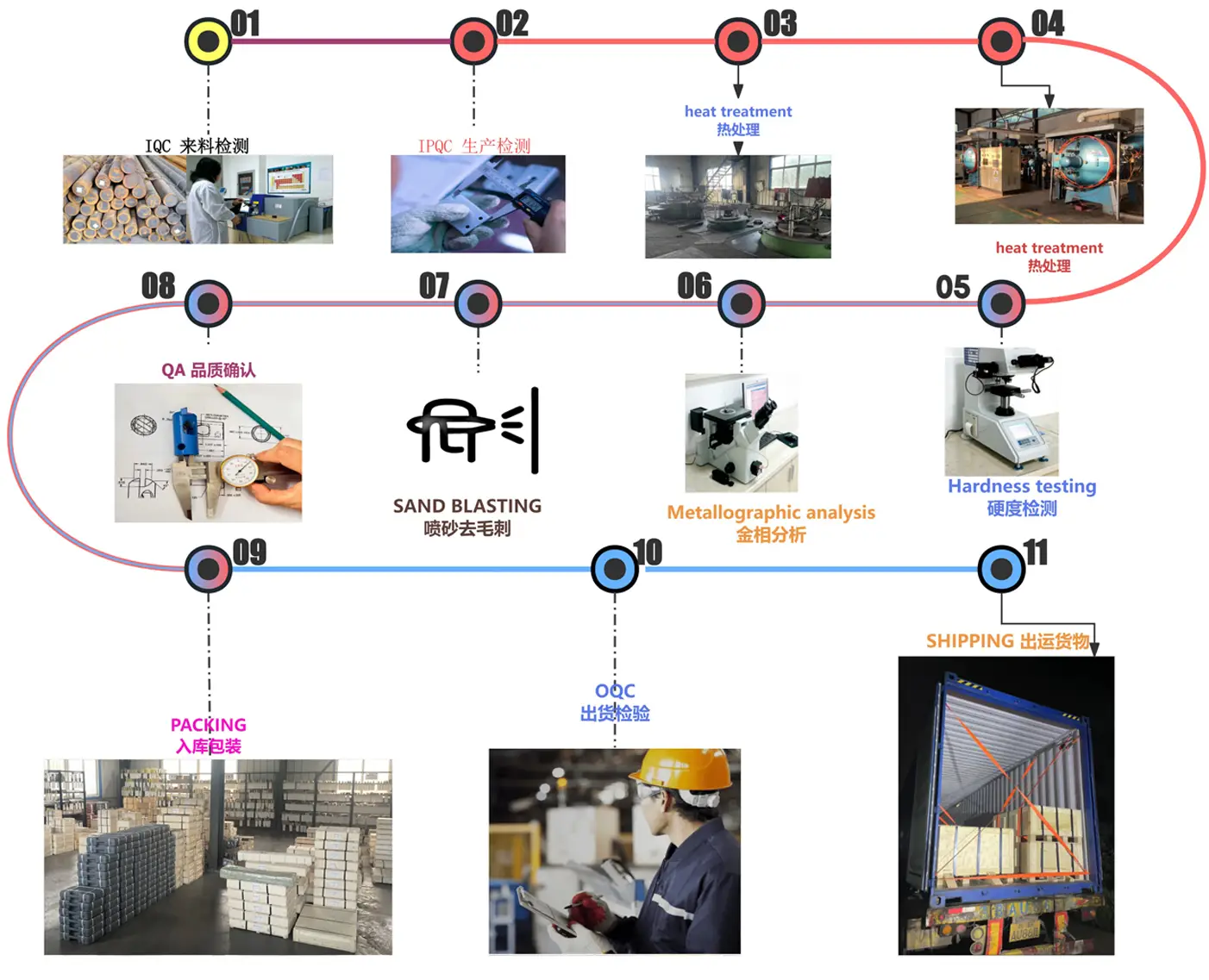

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE