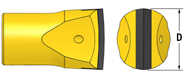

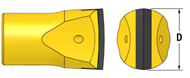

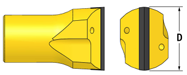

Taper Socket Chisel Drill Bit

Diameter:20-60mm.

Taper:degree:4°46′,6°, 7°,11°,12°

Bottom Hole: 22mm, 23mm

Steel grade︰40Cr, 42CrMo

Carbide brand:YK15.6, YK20,YG8C,YG9C,YG10C,YG11C

Key words:

Chisel Bit

Product Details

Description

Our Taper Socket chisel drill bits are made with high quality of best quality alloy steel bar and tungsten carbides, through heat treatment so that it can withstand the toughest rock drilling demands, and transmit intensive impact energy into the rock with the least possible loss of energy.

Performance

Taper Socket chisel drill bits showcases outstanding durability, reliability, and efficiency, making it an ideal choice for various mining operations.

Application

Taper Socket chisel drill bits are widely used in metallurgy mine, geological exploration, water conservancy construction, electricity, traffic, tunnel, quarry, national defence stone project etc.

Details Form

| Drill bit | Diameter | Tip size(mm) | Taper | Weight (kg) | HENGLONG P/N |

| mm | Height X Width | ||||

|

Horseshoe chisel bit

|

26 | 10x7 | 7° | 0.17 | 1111-26721-10/7-40-21 |

| 28 | 10x7 | 7° | 0.18 | 1111-28721-10/7-40-21 | |

| 30 | 13.5×8 | 7° | 0.22 | 1111-30722-13/8-40-13/14 | |

| 32 | 13.5×8 | 7° | 0.24 | 1111-32722-13/8-40-13/14 | |

| 34 | 13.5×8 | 7° | 0.27 | 1111-34722-13/8-40-13/14 | |

| 36 | 13.5×8 | 7° | 0.3 | 1111-36722-13/8-40-13/14 | |

| 38 | 13.5×8 | 7° | 0.33 | 1111-38723-13/8-40-13/14 | |

| 38 | 15×9 | 7° | 0.33 | 1111-38723-15/9-40-13/14 | |

| 40 | 13.5×9.2 | 7° | 0.38 | 1111-40723-13/9-40-14/11 | |

| 40 | 15×9.8 | 7° | 0.38 | 1111-40723-15/9-40-14/11 | |

| 42 | 13.5×9.2 | 7° | 0.41 | 1111-42723-13/9-40-14 | |

| 42 | 13.5×9.2 | 7° | 0.41 | 1111-42723-13/9-40-13/11 | |

| 43 | 13.5×9.2 | 7° | 0.42 | 1111-43723-13/9-40-14/13 | |

| 43 | 15×9.8 | 7° | t | 1111-43723-15/9-40-14/13 | |

| Drill bit | Diameter | Tip size(mm) | Taper | Weight (kg) | HRNGLONG P/N |

| mm | Height X Width | ||||

|

Oblique chipways chisel bit |

20 | 12×6 | 4° | 0.1 | 1112-20415-12/6-40-22 |

| 22 | 12×6 | 4° | 0.12 | 1112-22415-12/6-40-22 | |

| 24 | 12×6 | 4° | 0.14 | 1112-24415-12/6-40-22 | |

| 26 | 12×6 | 4° | 0.16 | 1112-26415-12/6-40-22 | |

| 28 | 13×8 | 7° | 0.19 | 1112-28722-13/8-40-22 | |

| 30 | 13.5×8 | 7° | 0.22 | 1112-30722-13/8-40-22 | |

| 32 | 13.5×8 | 7° | 0.24 | 1112-32722-13/8-40-22 | |

| 33 | 13.5×8 | 7° | 0.25 | 1112-33722-13/8-40-22 | |

| 34 | 13.5×8 | 7° | 0.27 | 1112-34722-13/8-40-22 | |

| 36 | 13.5×8 | 7° | 0.29 | 1112-36722-13/8-40-22 | |

| 38 | 13.5×8 | 7° | 0.34 | 1112-38723-13/8-40-22 | |

| 40 | 13.5×9.2 | 7° | 0.4 | 1112-40723-13/9-40-22 | |

| 41 | 13.5×9.2 | 7° | 0.41 | 1112-41723-13/9-40-22 | |

| 42 | 13.5×9.2 | 7° | 0.43 | 1112-42723-13/9-40-22 | |

|

Flat chipways chisel bit

|

38 | 16×10 | 7° | 0.36 | 1113-38723-16/10-40-22 |

| 40 | 16×10 | 7° | 0.38 | 1113-40723-16/10-40-22 | |

| 41 | 16×10 | 7° | 0.41 | 1113-41723-16/10-40-22 | |

| 42 | 16×10 | 7° | 0.43 | 1113-42723-16/10-40-22 | |

| 45 | 22×16×10 | 7° | 0.6 | 1113-45723-16/10-40-22 | |

| 46 | 22×16×10 | 7° | 0.61 | 1113-46723-16/10-40-22 | |

| 48 | 22×16×10 | 7° | 0.63 | 1113-48723-16/10-40-22 | |

| 50 | 22×16×10 | 7° | 0.65 | 1113-50723-16/10-40-22 | |

| 56 | 24×16×10 | 7° | 0.82 | 1113-56723-16/10-40-22 | |

| 60 | 26×16×10 | 7° | 0.91 | 1113-60723-16/10-40-22 | |

| 65 | 26×16×10 | 7° | 1.12 | 1113-65723-16/10-40-22 | |

| 80 | 36×16×10 | 7° | 1.4 | 1113-80723-16/10-40-22 | |

|

Oblique-flat chipways chisel bit

|

36 | 15×10 | 7° | 0.4 | 1114-36725-15/10-40-22 |

| 38 | 15×10 | 7° | 0.42 | 1114-38725-15/10-40-22 | |

| 41 | 15×10 | 7° | 0.47 | 1114-41725-15/10-40-22 | |

| 42 | 15×10 | 7° | 0.49 | 1114-42725-15/10-40-22 | |

| 43 | 15×10 | 7° | 0.51 | 1114-43725-15/10-40-22 | |

HENGLONG workshop and Process of manufacturing

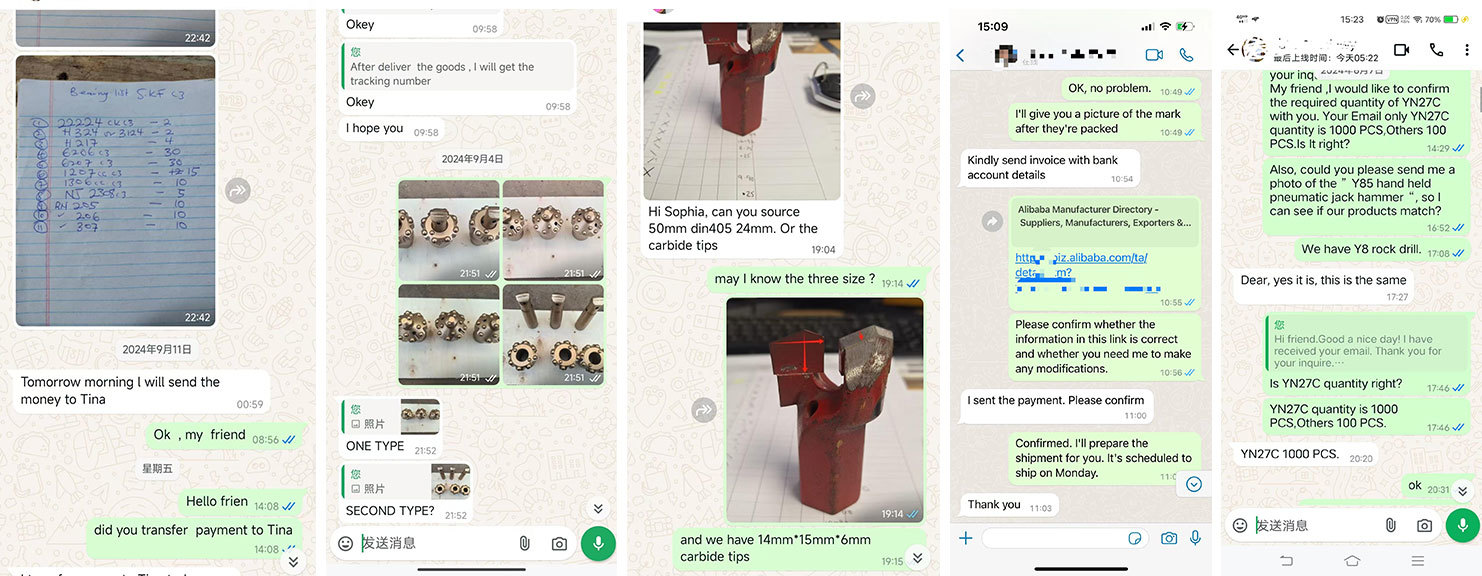

Packing and shipping

Factory

Customer visit

Production

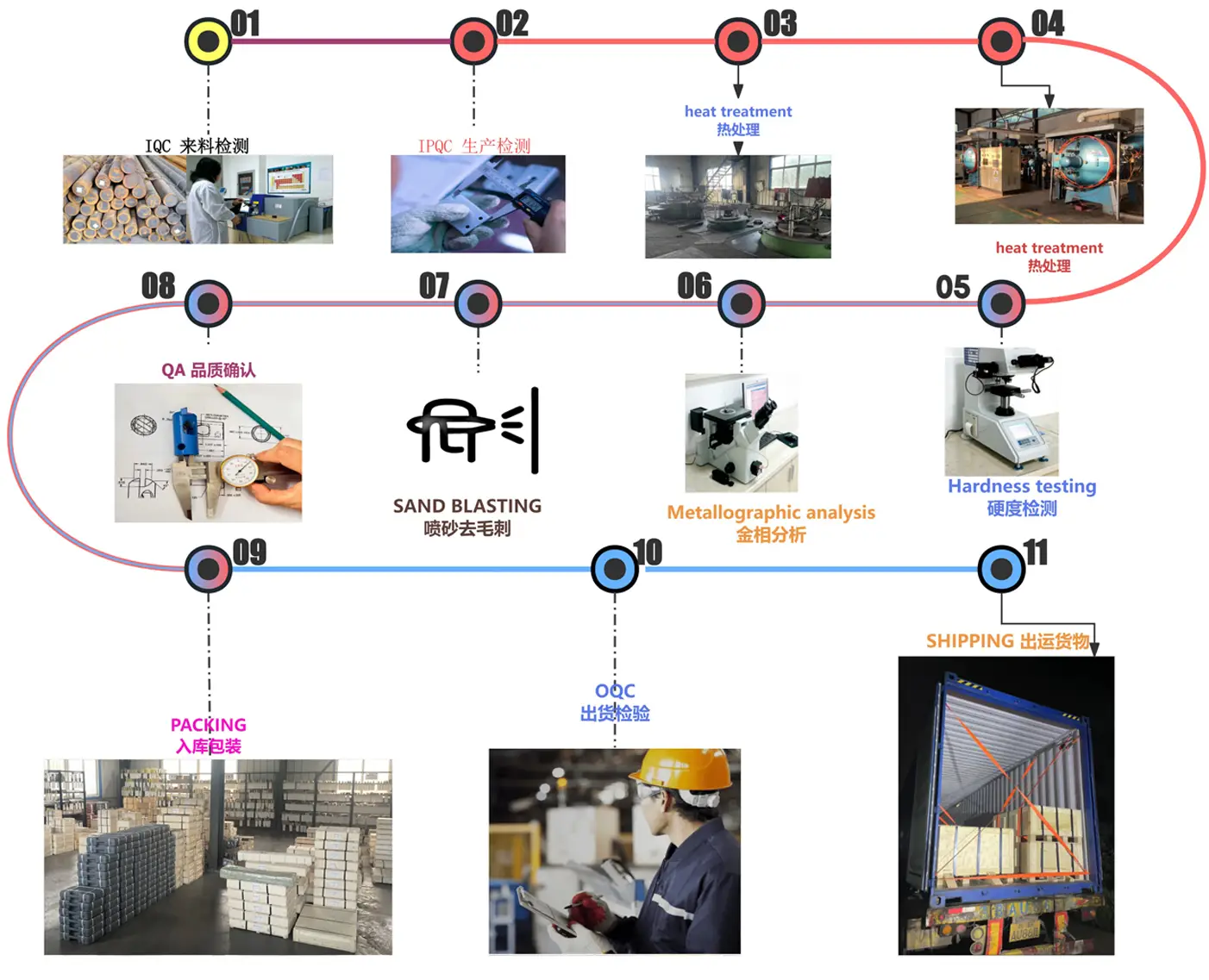

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE