Tapered Socket Cross Bit

Diameter: 28mm to 45mm

Socket inside diameter: 19mm / 22mm / 25mm

Length: 50mm to 80mm

Flushing Hole:2 or 3

Steel grade︰40Cr, 42CrMo

Carbide brand:YK15.6, YK20,YG8C,YG9C,YG10C,YG11C

Key words:

Cross Bit

Product Details

Description

The taper cross bits can be used under any rock drilling condition because of it's comprehensive adaptability. Compared with taper chisel bits, taper cross bits have a better drilling performance because carbide tips on cross bits doubled, which means carbides shape are cross type on drill bits. Taper cross bit is mainly used for hard or very hard rock formation.

Performance

Different types designed for different drilling scenarios and rock conditions;

High speed and drilling efficiency;

Cost-effective, good performance with reasonable price

Application

Tapered socket cross bits can be used under any rock drilling condition, it's hardly impacted by the model of drill rig and the rock performance.

Tapered socket cross bits are mainly available for digging into mine laneway and blasting holes in all drilling works matched with the taper drill rod. For different rock, we choose the different alloy to extend the working life of the drill bits.

Details Form

|

Drill bit |

Diameter |

Taper |

Weight (kg) |

HRNGLONG P/N |

||

|

mm |

inch |

|||||

|

7° Cross bit

|

30 |

1 3/16 |

7° |

0.29 |

1221-30722-12/8-40-22 |

|

|

32 |

1 1/4 |

7° |

0.31 |

1221-32722-12/8-40-22 |

||

|

33 |

1 19/64 |

7° |

0.33 |

1221-33722-12/8-40-22 |

||

|

34 |

1 11/32 |

7° |

0.34 |

1221-34722-12/8-40-22 |

||

|

35 |

1 3/8 |

7° |

0.36 |

1221-35722-12/8-40-22 |

||

|

36 |

1 27/64 |

7° |

0.37 |

1221-36722-12/8-40-22 |

||

|

38 |

1 1/2 |

7° |

0.43 |

1221-38723-12/8-40-22 |

||

|

40 |

1 37/64 |

7° |

0.47 |

1221-40723-12/8-40-22 |

||

|

41 |

1 5/8 |

7° |

0.49 |

1221-41723-12/8-40-22 |

||

|

42 |

1 21/32 |

7° |

0.51 |

1221-42723-12/8-40-22 |

||

|

43 |

1 11/16 |

7° |

0.53 |

1221-43723-12/8-40-22 |

||

|

45 |

1 3/4 |

7° |

0.58 |

1221-45723-14/8-40-22 |

||

|

48 |

1 7/8 |

7° |

0.67 |

1221-48723-14/8-40-22 |

||

|

50 |

1 31/32 |

7° |

0.72 |

1221-50723-14/8-40-22 |

||

|

55 |

2 1/4 |

7° |

0.92 |

1221-55725-16/10-40-22 |

||

|

60 |

2 3/8 |

7° |

1.19 |

1221-60725-16/10-40-22 |

||

|

11° Cross bit

|

29 |

1 9/64 |

11° |

0.25 |

1221-291122-12/8-42-22 |

|

|

30 |

1 3/16 |

11° |

0.26 |

1221-301122-12/8-42-22 |

||

|

32 |

1 1/4 |

11° |

0.30 |

1221-321122-12/8-42-22 |

||

|

33 |

1 19/64 |

11° |

0.32 |

1221-331122-12/8-42-22 |

||

|

35 |

1 3/8 |

11° |

0.36 |

1221-351122-12/8-42-22 |

||

|

36 |

1 27/64 |

11° |

0.39 |

1221-361122-12/8-42-22 |

||

|

38 |

1 1/2 |

11° |

0.43 |

1221-381122-12/8-42-22 |

||

|

41 |

1 5/8 |

11° |

0.49 |

1221-411122-14/8-42-22 |

||

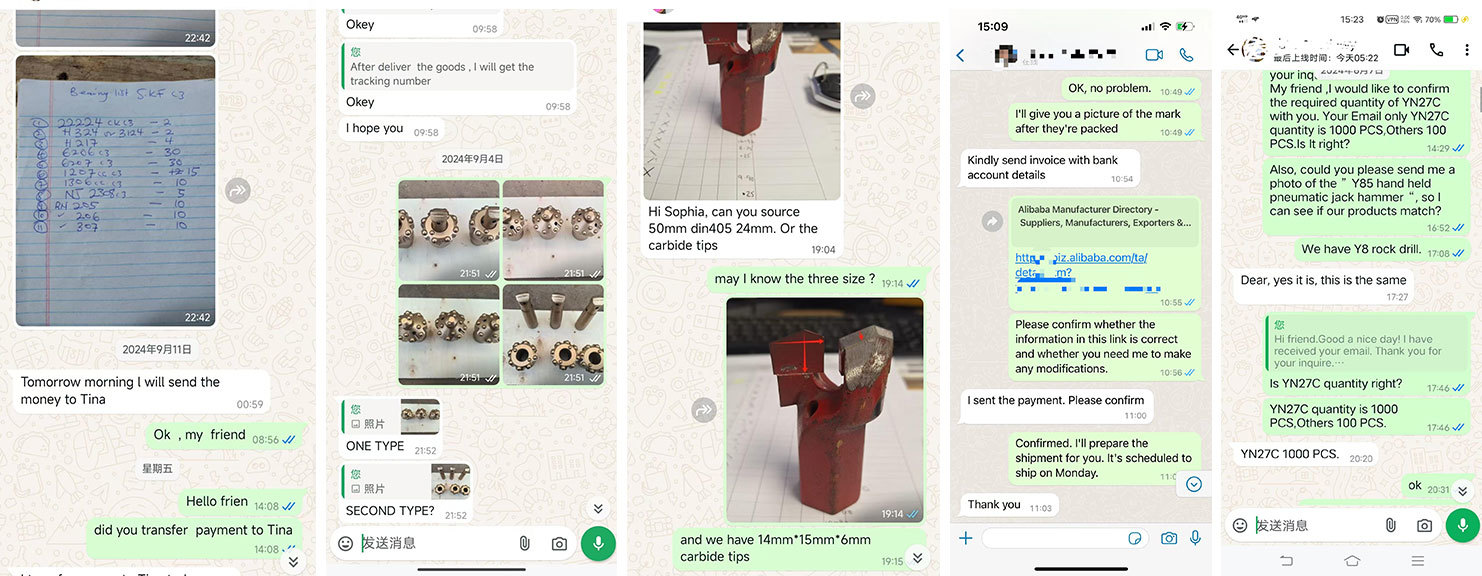

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

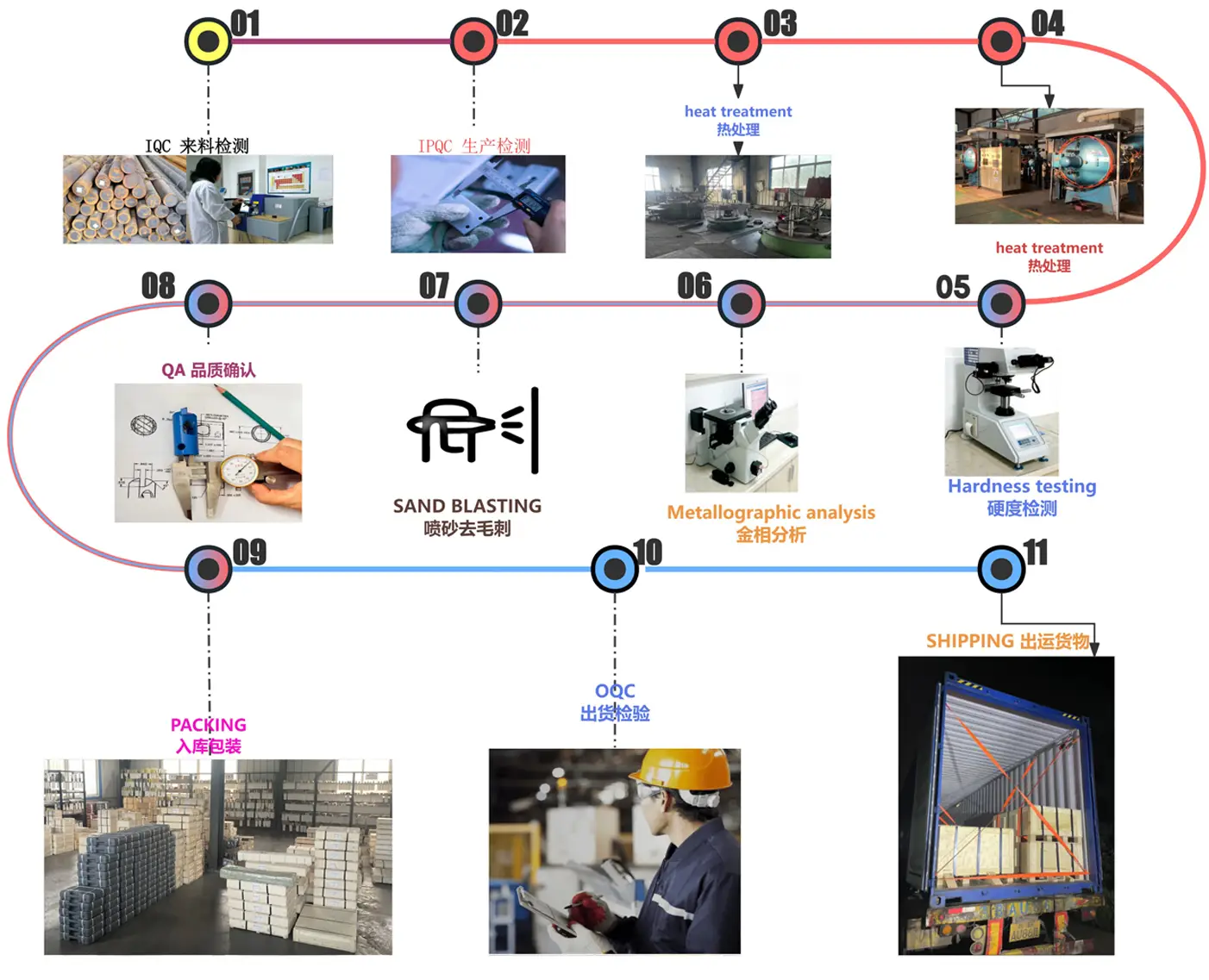

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE