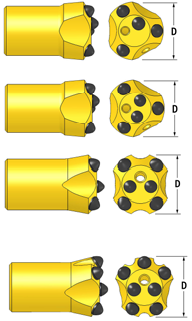

Tapered button bits

Length: 50mm

Tapered Degree: 11°

Conical Carbide size: 2*6mm /5*7mm

Painting:ZINC( inner hole)

Carbide Brand and Grade :ZCC/YK05

Steel grade :45CrNiMoVA

Key words:

Tapered Button Bit

Product Details

Description

Taper button bits make with high quality of raw material through special heat treatment, especially, tungsten carbide of tapered button bits are from Boart long year, widely applied in short hole drilling system for dimensional stone quarrying.

Diameter of bits from 30mm to 50mm with 4°46′, 6°, 7°, 11°, 12 °, premium alloy tapered drill steel with Hexagonal. 22mm and Hexagonal. 25mm, The deliver capacity are very strong,The monthly supply can reach 50,000 pieces and can completely meet customer's requirements on delivery design, number of buttons is 4, 5, 6, 7, 8, 9.The bit of 7 buttons is very popular for hold held (short holes ) and blast drilling system.

Performance

Comparing with tapered chisel bits and tapered cross bits, tapered button bits has higher technology, much longer primary drilling time and higher drilling efficiency, so that the button bit is popular among the users.

Applification:

Our taper drilling tools include taper drill bits and taper drill rod, and taper drill bits come into two types, taper button bits, taper chisel drill bits. These drill tools are mainly equipped on rock drilling equipment, well drilling equipment and oil field equipment. They are widely used for rock drilling, blasting holes and other drill works in quarries, coal mines, rod and dam constructions and other similar projects.

Details Form

|

11° Drill bit |

Diameter |

No.× button diameter |

Flushing hole |

Weight approx kg |

HENGLONG P/N |

||||

|

mm |

inch |

Center |

Gauge |

Angle |

Front |

Side |

|||

|

Button bit,short skirt

|

32 |

1 1/4 |

1×8 |

3×8 |

35° |

1 |

2 |

0.24 |

1431-321122-18/38-45-51 |

|

33 |

1 19/64 |

2×7 |

4×7 |

40° |

1 |

1 |

0.25 |

1431-331122-27/47-45-51 |

|

|

34 |

1 21/64 |

2×7 |

4×7 |

40° |

1 |

1 |

0.29 |

1431-341122-27/47-45-51 |

|

|

35 |

1 3/8 |

2×7 |

5×7 |

35° |

2 |

1 |

0.33 |

1431-351122-27/57-45-51 |

|

|

36 |

1 13/32 |

1×8 |

3×9 |

40° |

1 |

1 |

0.36 |

1431-361122-18/39-45-51 |

|

|

36 |

1 13/32 |

2×7 |

4×7 |

40° |

2 |

1 |

0.36 |

1431-361122-27/47-45-51 |

|

|

36 |

1 13/32 |

2×7 |

5×8 |

35° |

1 |

1 |

0.36 |

1431-361122-27/58-45-51 |

|

|

38 |

1 1/2 |

1×9 |

3×9 |

40° |

1 |

1 |

0.39 |

1431-381122-19/39-45-51 |

|

|

38 |

1 1/2 |

2×8 |

3×9 |

40° |

1 |

2 |

0.39 |

1431-381122-28/39-45-51 |

|

|

38 |

1 1/2 |

2×7 |

5×8 |

35° |

1 |

1 |

0.39 |

1431-381122-27/58-45-51 |

|

|

38 |

1 1/2 |

2×7 |

5×9 |

35° |

2 |

1 |

0.39 |

1431-381122-27/59-45-51 |

|

|

40 |

1 9/16 |

1×9 |

3×9 |

40° |

1 |

1 |

0.40 |

1431-401122-19/39-45-51 |

|

|

40 |

1 9/16 |

2×8 |

3×9 |

40° |

1 |

1 |

0.40 |

1431-401122-28/39-45-51 |

|

|

40 |

1 9/16 |

2×7 |

5×9 |

35° |

1 |

1 |

0.40 |

1431-401122-27/59-45-51 |

|

|

41 |

1 5/8 |

2×8 |

5×9 |

35° |

2 |

1 |

0.41 |

1431-411122-28/59-45-51 |

|

|

Button bit,body length 60mm

|

33 |

1 19/64 |

2×7 |

6×7 |

35° |

2 |

1 |

0.32 |

1431-331122-27/67-45-51 |

|

34 |

1 21/64 |

2×7 |

5×7 |

35° |

1 |

1 |

0.32 |

1431-341122-27/57-45-51 |

|

|

35 |

1 3/8 |

2×7 |

5×7 |

40° |

1 |

2 |

0.35 |

1431-351122-27/57-45-51 |

|

|

36 |

1 13/32 |

2×7 |

5×8 |

35° |

1 |

1 |

0.39 |

1431-361122-27/58-45-51 |

|

|

38 |

1 1/2 |

2×7 |

5×9 |

35° |

1 |

1 |

0.42 |

1431-381122-27/59-45-51 |

|

|

38 |

1 1/2 |

2×8 |

6×8 |

35° |

2 |

1 |

0.44 |

1431-381122-28/68-45-51 |

|

|

41 |

1 5/8 |

2×8 |

6×8 |

35° |

2 |

1 |

0.48 |

1431-411122-28/68-45-51 |

|

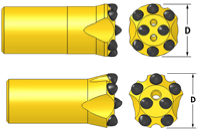

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

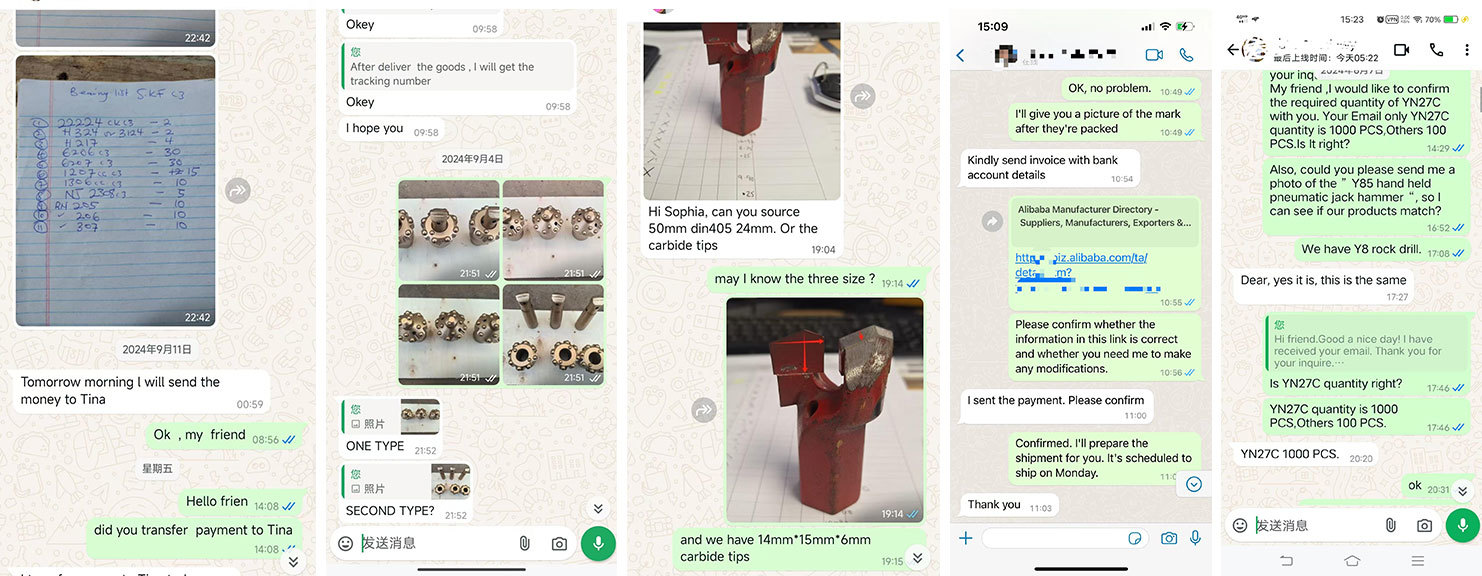

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE