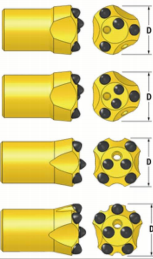

Top hammer button bit

Diameter:34mm

Body length :50mm

Tapered Degree :11°

Carbide Design:Conical

Carbide size:6*7mm

Key words:

Tapered Button Bit

Product Details

Description

Rock drill bits factory HENGLONG Drill produces Top hammer button bit:Top hammer button bits are different with thread button bits as long hole bits to use taper match with bit rods to be used for air leg or hand held driller in stone quarrying and mining.

For high quality small-hole drilling consumables ( tools, accessories , spareparts ), We will choose to use tungsten carbide of T6,featuring good wear-resistance and toughness. This type of carbide has already been proved to be the best in China and been competing with those big names worldwide for quite a long time. Meanwhile,we will choose to use superior steel suitable for hot insertion technology, by which the drilling bits body will hold the carbide buttons so tightly that reduce the risk of buttons’ dropping out of the holes. In order to better resist the abrasiveness of rock, spherical shape will be a good option for the carbide if high speed is not a necessity.

Performance

Top hammer button bits performace

(1)Connect shank Size: Φ19, Φ22, Φ25 at most

(2)Bit Diameter: 32mm,34mm,35mm,36mm, 38mm,40mm

(3)Tapered connection:4°46′,6°,7°,11°,12° etc.

(4)Material: Alloy Steel Bar 45CrNiMoV, Tungsten Carbide Tips YK05 or T6.

(5)Button Shape: Semi-Ballistic; Face Type: Flat Face; Bit Body: Standard

(6)Qty of button: 5,7, 8 pcs

(7)main market: India, Saudi Arabia, Chile, South Africa, stone countries consume very much.

Application

Top hammer button bits are used for tunneling, mining,quarrying, Well drilling,mining drilling,ore drilling

• Suitable for small hole range

• Widely used in Dimensional Stone Quarrying Industry

• Widely used in Underground Mining Industry

Details Form

| Drill bit | Diameter | Button No.×Dia. | Flushing hole | Weight (kg) | HENGLONG P/N | |||

| mm | Gauge | Center | Angle | Front | Side | |||

|

Button bit ,Short skirt

|

32 | 3×8 | 1×8 | 35° | 1 | 1 | 0.24 | 1431-32722-18/38-40-53 |

| 33 | 5×7 | 2×7 | 35° | 2 | 1 | 0.26 | 1431-33722-27/57-42-53 | |

| 34 | 4×7 | 2×7 | 40° | 1 | 1 | 0.29 | 1431-34722-27/47-42-53 | |

| 35 | 5×8 | 2×7 | 35° | 1 | 1 | 0.33 | 1431-35722-27/58-42-53 | |

| 36 | 3×9 | 1×8 | 40° | 1 | 1 | 0.37 | 1431-36722-18/39-42-53 | |

| 36 | 5×8 | 2×7 | 35° | 1 | 1 | 0.37 | 1431-36722-27/58-42-53 | |

| 38 | 3×9 | 1×8 | 35° | 1 | 1 | 0.38 | 1431-38723-18/39-42-53 | |

| 38 | 5×8 | 2×7 | 35° | 1 | 1 | 0.38 | 1431-38723-27/58-42-53 | |

| 38 | 5×9 | 2×7 | 40° | 2 | 1 | 0.38 | 1431-38723-27/59-42-53 | |

| 40 | 3×9 | 1×8 | 30° | 1 | 1 | 0.40 | 1431-40723-18/39-40-53 | |

| 40 | 3×10 | 1×9 | 30° | 1 | 1 | 0.40 | 1431-40723-19/310-40-53 | |

| 40 | 3×9 | 1×9 | 35° | 1 | 1 | 0.40 | 1431-40723-19/39-42-53 | |

| 40 | 5×9 | 2×7 | 35° | 1 | 1 | 0.40 | 1431-40723-27/59-42-53 | |

| 42 | 3×9 | 1×8 | 30° | 1 | 1 | 0.43 | 1431-42723-18/39-40-53 | |

| 42 | 3×10 | 1×9 | 30° | 1 | 1 | 0.43 | 1431-42723-19/310-40-53 | |

| 42 | 3×9 | 1×9 | 35° | 1 | 1 | 0.43 | 1431-42723-19/39-42-53 | |

| 42 | 5×9 | 2×8 | 35° | 1 | 1 | 0.43 | 1431-42723-28/59-42-53 | |

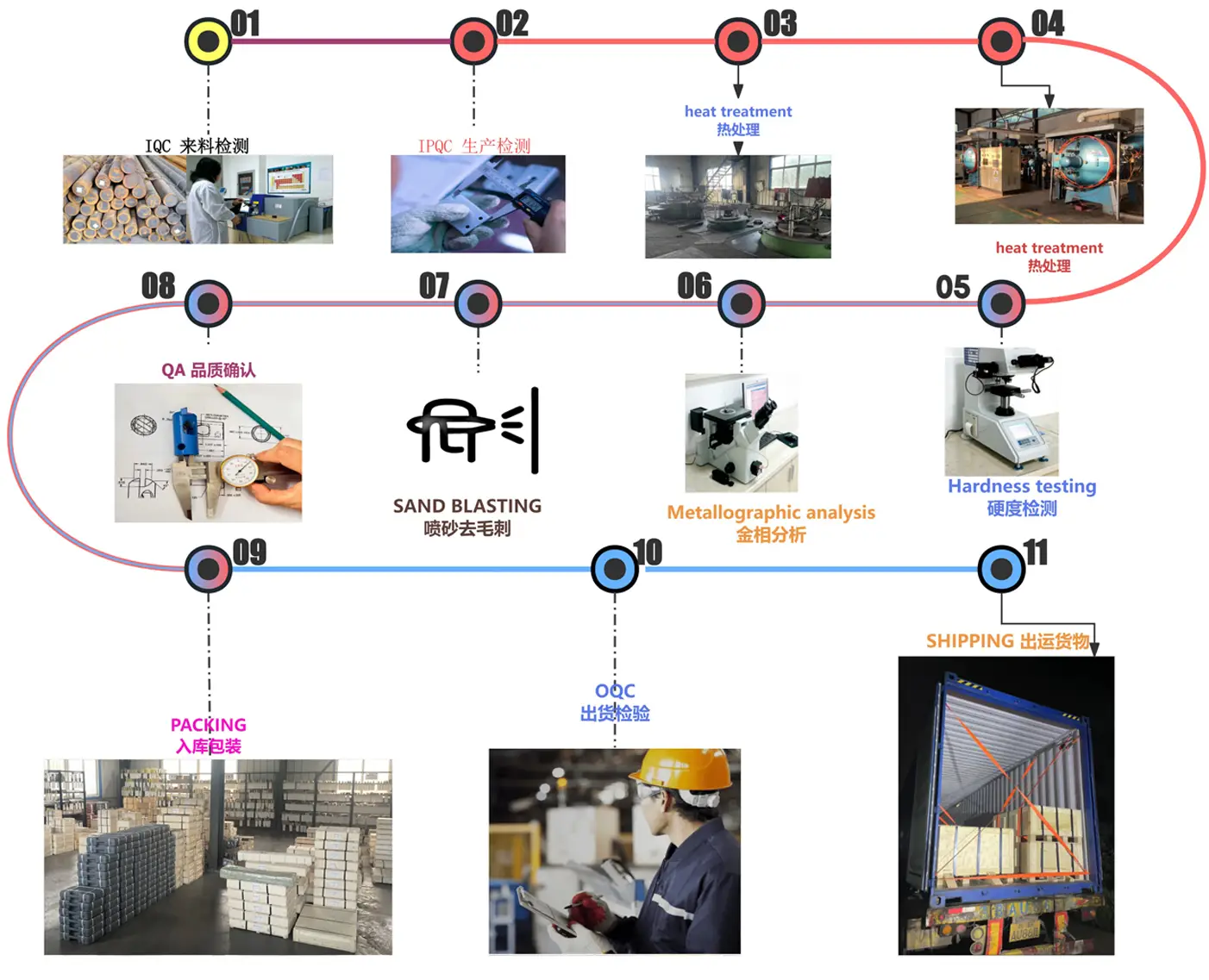

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

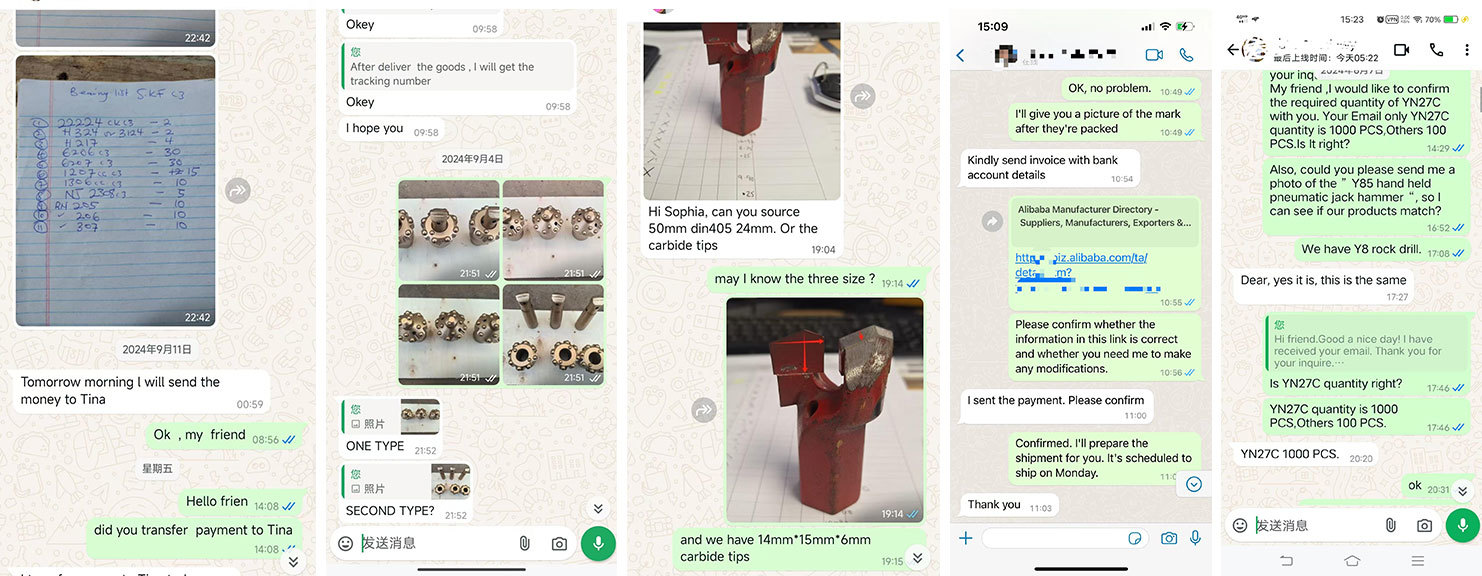

Customer visit

Production

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE