hollow anchor bar

Thread:R25

Outer Dia.:25mm

Inner Dia.:14mm

Weight:2.3kg/m

Surface treatment:Epoxy Coating or Hot-dipped Galvanization

Steel grade:42CrMo

Key words:

Rock Bolt

Product Details

Description

The rolling process enhances the yield strength of the steel. The fully threaded hollow anchor bar allows drilling using a sacrificial drill bit at one end and another end to connect to the standard drill tool that works simultaneously for drilling and grouting. Full threading length of SDA makes it more beneficial to grate bonding to grout and tube and enable for drill rig connections and couplings.

Application

Slope stabilization

Self-Drilling Anchors are very suitable for weathered or un-consolidated rock stabilization. This technique is a more superior form of stabilization because the SDA technique is a relatively easy and fast method of installation compared to the outdated methods.

Foundations with micro piles

SDAs can be used like monopoles and micropile types because these are drilled piles composed of steel reinforcement with injected grout. These anchors are used like micropile type to stabilize the ground and related foundation problems. These anchors are suitable for tension and compression loads at varying ground conditions.

Tunneling

Self-drilling anchors are most suitable for the stabilization of tunnel strengthening works. Mostly for the soft rock and overburden soil conditions, the SDA’s are apt for rooftop protection.

Specification

|

NO. |

Surface |

Outer Dia. |

Inner Dia. |

Weight |

Steel Type |

Thread Type |

Ultimate Load |

Yield Load |

Part Number |

|

1 |

Epoxy Coating or Hot-dipped Galvanization |

25 |

14 |

2.30 |

EN10083-1=4140=42CrMo |

L/R |

200 |

150 |

R25N-14 |

|

2 |

32 |

21 |

2.90 |

280 |

230 |

R32N-21 |

|||

|

3 |

18.5 |

3.40 |

280 |

230 |

R32N-18.5 |

||||

|

4 |

16 |

3.60 |

360 |

280 |

R32S-16 |

||||

|

5 |

15.5 |

3.80 |

405 |

350 |

R32SS-15.5 |

||||

|

6 |

38 |

19 |

5.50 |

500 |

400 |

R38N-19 |

|||

|

7 |

21 |

4.80 |

500 |

400 |

R38N-21 |

||||

|

8 |

51 |

36 |

7.00 |

550 |

450 |

R51L-36 |

|||

|

9 |

33 |

8.40 |

800 |

630 |

R51N-33 |

||||

|

10 |

30 |

11 |

3.41 |

320 |

260 |

T30-11 |

|||

|

11 |

14 |

2.87 |

275 |

220 |

T30-14 |

||||

|

12 |

16 |

2.70 |

245 |

190 |

T30-16 |

||||

|

13 |

40 |

16 |

6.60 |

660 |

525 |

T40-16 |

|||

|

14 |

20 |

5.60 |

540 |

425 |

T40-20 |

||||

|

15 |

52 |

26 |

9.87 |

925 |

730 |

T52-26 |

|||

|

16 |

64 |

44 |

11.60 |

1042 |

900 |

RR64-44 |

|||

|

17 |

73 |

53 |

14.10 |

1160 |

970 |

T73-53 |

|||

|

18 |

56 |

10.75 |

1035 |

830 |

T73-56 |

||||

|

19 |

45 |

17.80 |

1585 |

1270 |

T73-45 |

||||

|

20 |

35 |

21.20 |

1865 |

1430 |

T73-35 |

||||

|

21 |

76 |

45 |

15.00 |

1900 |

1500 |

T76S-45 |

|||

|

22 |

51 |

19.70 |

1600 |

1200 |

T76N-51 |

||||

|

23 |

54 |

15.80 |

1620 |

1220 |

RR76-54 |

||||

|

24 |

103 |

78 |

25.30 |

2270 |

1800 |

T103-78 |

|||

|

25 |

51 |

44.60 |

3660 |

2670 |

T103-51 |

||||

|

26 |

108 |

82 |

27.90 |

2580 |

1980 |

RR108-82 |

|||

|

27 |

111 |

82 |

25.00 |

2640 |

2000 |

T111L-82 |

|||

|

28 |

75 |

34.50 |

3650 |

2750 |

T111N-75 |

||||

|

29 |

127 |

111 |

28.90 |

2320 |

2030 |

T127-111 |

|||

|

30 |

130 |

60 |

75.00 |

7940 |

5250 |

T130-60 |

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

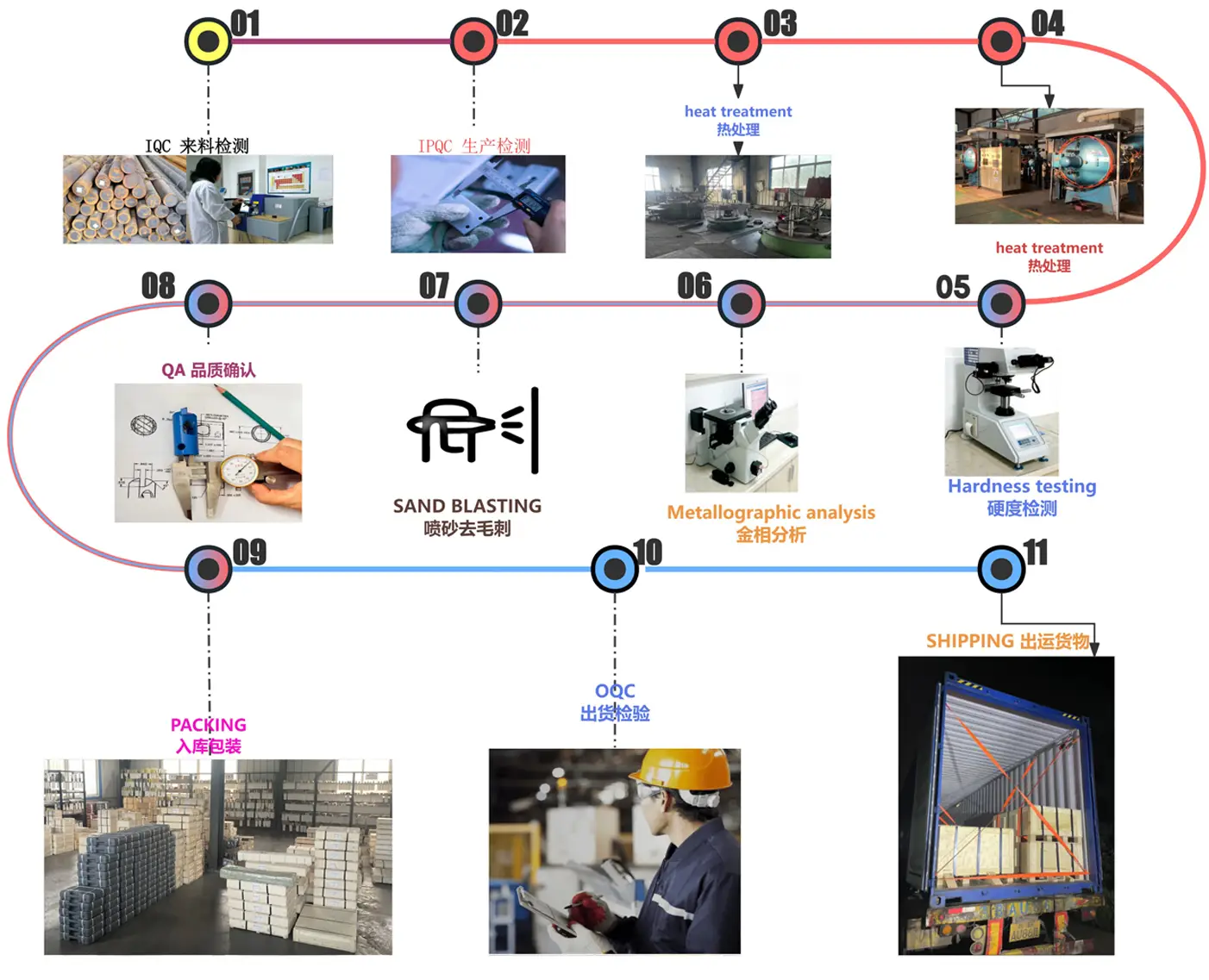

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE