self drilling anchor bolt

Lenghth:3000mm

Weight:24.9kg

Material:23CrNi3Mo

Key words:

Rock Bolt

Product Details

Description

Self-drilling anchors are the advanced type of fully threaded hollow steel tube rods. SDA is a fully threaded rod with an inner and outer diameter hollow steel tube. It is provided with a sacrificial drill bit at the end to facilitate the drilling process, coupler to join two SDA bars, screw nut, base plate, etc. The hollow steel tube has one side sacrificial drill bit and, at another end, tied with nut and steel base plate. A hollow steel tube is placed in the center of the drill hole using a centralizer to maintain its position. The grout, which covers the SDA periphery, protects the SDA under aggressive environment conditions with simultaneous grout ground and grout bar interaction throughout the threaded bond length. Self-drilling sacrificial drill varies based on the rock or soil conditions.

The hollow steel tube has more bending strength and more circumference area compared to the solid steel bar (soil nail) with the same cross-sectional area. Due to these benefits of self-drilling anchor, it has advantages over other for reinforcing solid bars, soil nails, and rock anchors. SDA installation can be done by a small drilling machine that can move in difficult access areas and provide slope protection work in difficult reach. Its application, not just only application to soil and slope reinforcement, but also for tunnel application like forepoling for tunnel advancement.

Components of SDA

Drill Bit

One of the main components in this technology is a sacrificial drill bit. It helps the drilling and inserting of SDA operation at the same time. This increases the productivity of the SDA installation. The sacrificial drill bit quality defines improving the SDA technique’s penetration rate, performance, and cost-efficiency.

Hollow Anchor Bar

The rolling process enhances the yield strength of the steel. The fully threaded hollow bar allows drilling using a sacrificial drill bit at one end and another end to connect to the standard drill tool that works simultaneously for drilling and grouting. Full threading length of SDA makes it more beneficial to grate bonding to grout and tube and enable for drill rig connections and couplings.

Coupler

The couplers’ main aim is to provide the connection between seating of each hollow tube face-to-face connection. This is the main component for the energy transmission from end to end connection of anchor and provides maximum percussive energy to drill bit with lesser losses.

plate

Bearing plate with sufficient thickness of steel plates having a central hole required at the face of SDA. The main function of this plate is to transfer the tension load of SDA to the ground.

nut

The hexagonal nuts are made of high strength steel with properly made by all edges to satisfy the demands of anchor specifications and other operations.

centralizer

Centralizers are used to centre the hollow bars within the borehole and to ensure the correct grout cover of the load-bearing element according to the relevant standards and as specified in

the approvals.

Application

Slope stabilization

Self-Drilling Anchors are very suitable for weathered or un-consolidated rock stabilization. This technique is a more superior form of stabilization because the SDA technique is a relatively easy and fast method of installation compared to the outdated methods.

Foundations with micro piles

SDAs can be used like monopoles and micropile types because these are drilled piles composed of steel reinforcement with injected grout. These anchors are used like micropile type to stabilize the ground and related foundation problems. These anchors are suitable for tension and compression loads at varying ground conditions.

Tunneling

Self-drilling anchors are most suitable for the stabilization of tunnel strengthening works. Mostly for the soft rock and overburden soil conditions, the SDA’s are apt for rooftop protection.

Specification

|

nut (Hex/Dome) |

|

|

|

|

|

|

|

|

|

Description |

R32 |

R38 |

R51 |

T51 |

T76 |

T103 |

T108 |

Unit |

|

Key size |

46 |

50 |

75 |

100 |

100 |

125 |

125 |

mm |

|

length |

45 |

60 |

70 |

80 |

80 |

80 |

80 |

mm |

|

Weight |

0.4 |

0.5 |

1.6 |

2.7 |

2.4 |

2.9 |

3.1 |

kg |

Coupler

|

NO. |

Adaptable |

Outer Dia. |

Length |

Hardness |

Weight |

Steel Type |

Thread Type |

|

1 |

T30 |

38 |

105 |

25-30 |

0.45 |

EN10083-1=4140=42CrMo |

L/R |

|

2 |

T40 |

54 |

140 |

25-30 |

1.20 |

||

|

3 |

T52 |

70 |

160 |

25-30 |

2.30 |

||

|

4 |

T73 |

95 |

235 |

25-30 |

4.30 |

||

|

5 |

T76N |

95 |

200 |

25-30 |

4.30 |

||

|

6 |

T76S |

97 |

220 |

25-30 |

5.40 |

||

|

7 |

T103 |

123 |

255 |

25-30 |

7.45 |

||

|

8 |

T108 |

130 |

220 |

25-30 |

7.4 |

Centralizer

|

No. |

Outer Dia. |

Length |

Hole Dia |

Steel Type |

Weight |

|

1 |

68 |

35 |

35 |

CK45 |

0.35 |

|

2 |

70 |

35 |

40 |

0.36 |

|

|

3 |

85 |

40 |

52 |

0.52 |

|

|

4 |

95 |

40 |

67 |

0.53 |

|

|

5 |

125 |

40 |

67 |

0.86 |

|

|

6 |

140 |

50 |

80 |

1.25 |

|

|

7 |

170 |

60 |

112 |

2.15 |

|

|

8 |

65 |

35 |

35 |

0.30 |

|

|

9 |

70 |

35 |

40 |

0.36 |

|

|

10 |

85 |

40 |

53 |

0.52 |

|

|

11 |

103 |

60 |

150 |

1.4 |

|

|

12 |

110 |

50 |

80 |

0.75 |

|

|

13 |

140 |

60 |

112 |

1.25 |

|

|

14 |

150 |

60 |

108 |

|

1.62 |

Hollow Anchor Bar

|

NO. |

Surface |

Outer Dia. |

Inner Dia. |

Weight |

Steel Type |

Thread Type |

Ultimate Load |

Yield Load |

Part Number |

|

1 |

Epoxy Coating or Hot-dipped Galvanization |

25 |

14 |

2.30 |

EN10083-1=4140=42CrMo |

L/R |

200 |

150 |

R25N-14 |

|

2 |

32 |

21 |

2.90 |

280 |

230 |

R32N-21 |

|||

|

3 |

18.5 |

3.40 |

280 |

230 |

R32N-18.5 |

||||

|

4 |

16 |

3.60 |

360 |

280 |

R32S-16 |

||||

|

5 |

15.5 |

3.80 |

405 |

350 |

R32SS-15.5 |

||||

|

6 |

38 |

19 |

5.50 |

500 |

400 |

R38N-19 |

|||

|

7 |

21 |

4.80 |

500 |

400 |

R38N-21 |

||||

|

8 |

51 |

36 |

7.00 |

550 |

450 |

R51L-36 |

|||

|

9 |

33 |

8.40 |

800 |

630 |

R51N-33 |

||||

|

10 |

30 |

11 |

3.41 |

320 |

260 |

T30-11 |

|||

|

11 |

14 |

2.87 |

275 |

220 |

T30-14 |

||||

|

12 |

16 |

2.70 |

245 |

190 |

T30-16 |

||||

|

13 |

40 |

16 |

6.60 |

660 |

525 |

T40-16 |

|||

|

14 |

20 |

5.60 |

540 |

425 |

T40-20 |

||||

|

15 |

52 |

26 |

9.87 |

925 |

730 |

T52-26 |

|||

|

16 |

64 |

44 |

11.60 |

1042 |

900 |

RR64-44 |

|||

|

17 |

73 |

53 |

14.10 |

1160 |

970 |

T73-53 |

|||

|

18 |

56 |

10.75 |

1035 |

830 |

T73-56 |

||||

|

19 |

45 |

17.80 |

1585 |

1270 |

T73-45 |

||||

|

20 |

35 |

21.20 |

1865 |

1430 |

T73-35 |

||||

|

21 |

76 |

45 |

15.00 |

1900 |

1500 |

T76S-45 |

|||

|

22 |

51 |

19.70 |

1600 |

1200 |

T76N-51 |

||||

|

23 |

54 |

15.80 |

1620 |

1220 |

RR76-54 |

||||

|

24 |

103 |

78 |

25.30 |

2270 |

1800 |

T103-78 |

|||

|

25 |

51 |

44.60 |

3660 |

2670 |

T103-51 |

||||

|

26 |

108 |

82 |

27.90 |

2580 |

1980 |

RR108-82 |

|||

|

27 |

111 |

82 |

25.00 |

2640 |

2000 |

T111L-82 |

|||

|

28 |

75 |

34.50 |

3650 |

2750 |

T111N-75 |

||||

|

29 |

127 |

111 |

28.90 |

2320 |

2030 |

T127-111 |

|||

|

30 |

130 |

60 |

75.00 |

7940 |

5250 |

T130-60 |

plate

|

No. |

Adaptable |

Size |

Thickness |

Hole Dia |

Weight |

Steel Type |

|

1 |

R25N |

150*150 |

8 |

30 |

1.40 |

Q235B |

|

2 |

R32L/R32N |

200*200 |

10 |

35 |

3.00 |

|

|

3 |

R32S/R32SS |

200*200 |

12 |

35 |

3.70 |

|

|

4 |

38N |

200*200 |

12 |

41 |

3.60 |

|

|

5 |

51L |

200*200 |

30 |

60 |

8.80 |

|

|

6 |

51N |

200*200 |

40 |

60 |

18.50 |

|

|

7 |

T30 |

200*200 |

8 |

36 |

2.45 |

|

|

8 |

T40 |

200*200 |

12 |

54 |

3.50 |

|

|

9 |

T52 |

220*220 |

35 |

65 |

12.15 |

|

|

10 |

T73 |

250*250 |

40 |

80 |

18.50 |

|

|

11 |

T76N/T76S |

250*250 |

40 |

80 |

19.50 |

|

|

12 |

T103 |

300*300 |

50 |

110 |

33.00 |

HENGLONG workshop and Process of manufacturing

Packing and shipping

Factory

Customer visit

Production

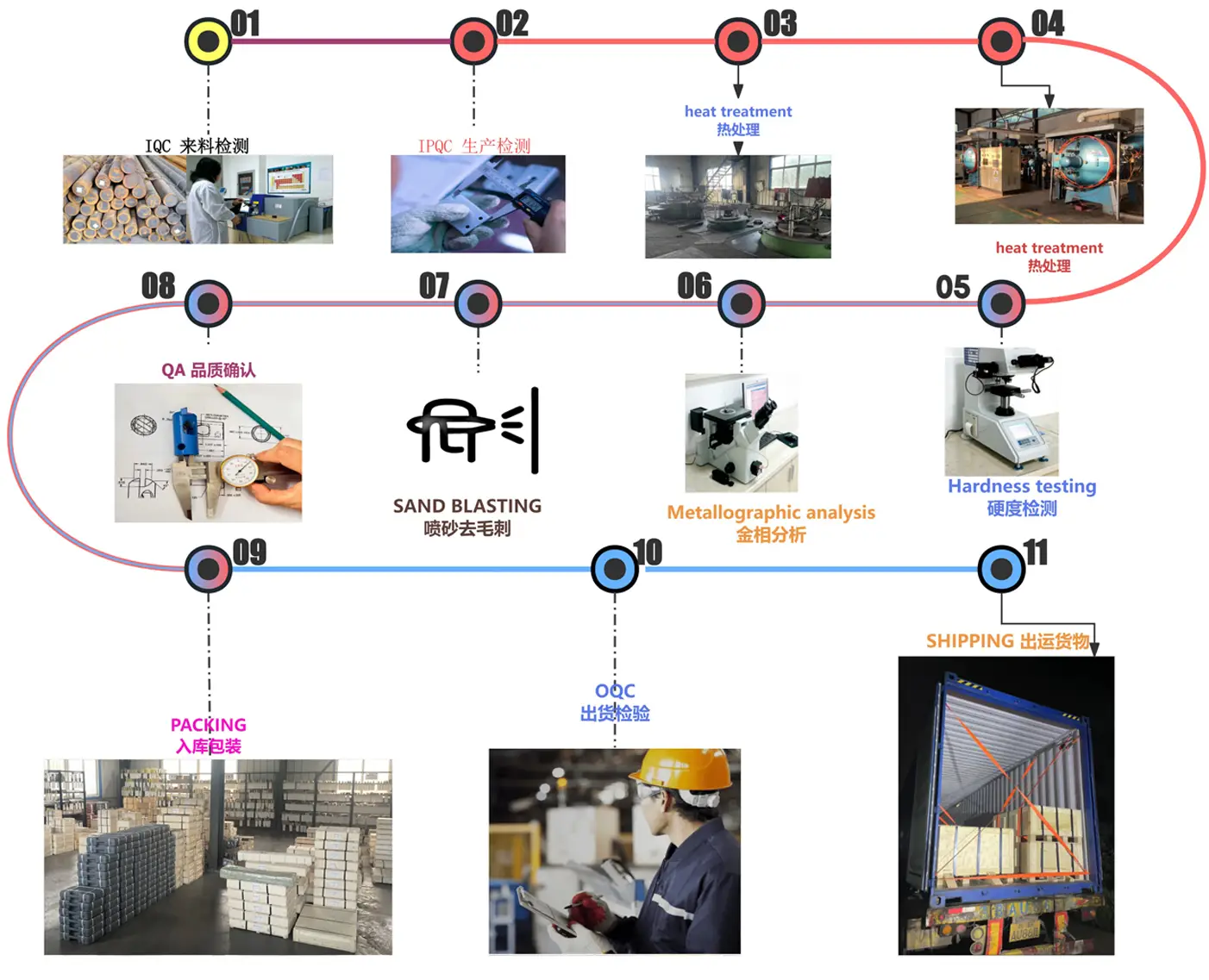

QUALITY INSPECTION PROCESS

Product quality is one of the core links in the development and growth of Yanggu Henglong Engineering Co., Ltd. Our company has strict internal and external inspection processes to ensure the quality of our products. Our inspection process for our products is as follows.

Related Products

MESSAGE